I recently bought a 1986 Laser. It's in great shape, except for the mast step. The previous owner says that while it leak slightly, it's structurally sound, and that he has taken it in high winds (20+ knots) without issue.

From the pictures, you can see that it is crudely sealed with silicone. There outside layer of fiberglass seems to be separating from the rest of the tube, which gives the appearance of a crack. From what I can see it's only on this outermost layer. I'm unsure what's under the rest of the silicone.

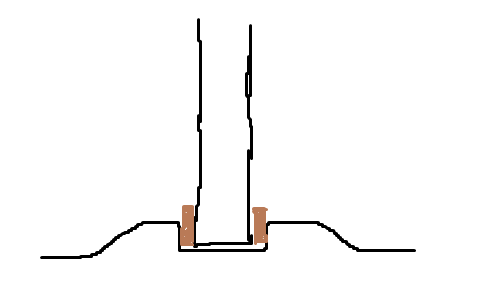

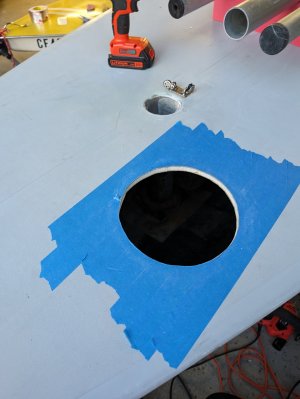

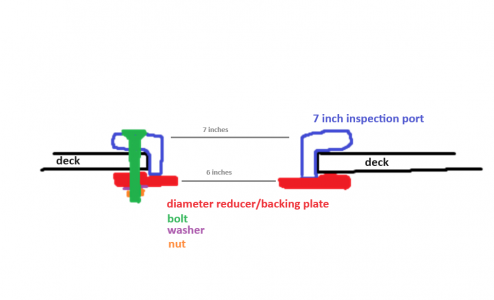

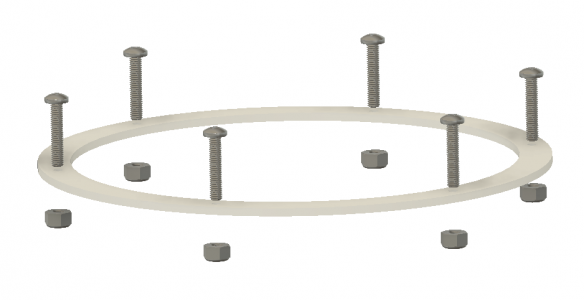

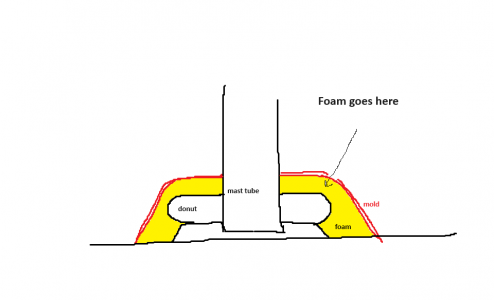

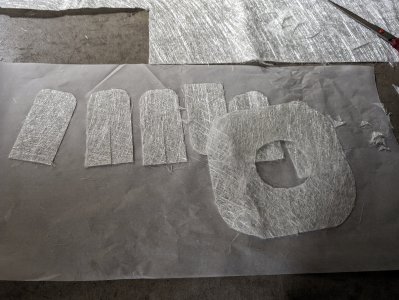

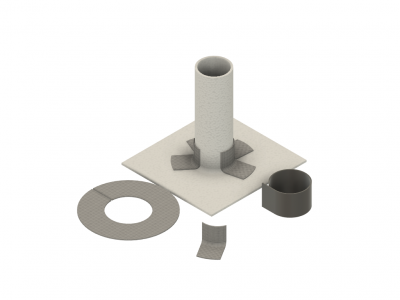

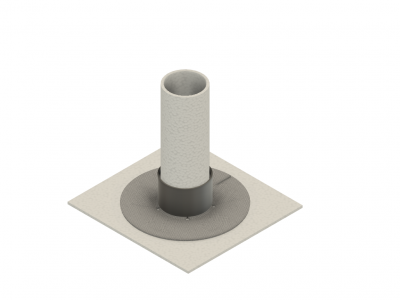

Do you think that this is worth repairing? Or should I just stick with the silicone and add more if it reopens the leak. If I were to go with a repair, I think my plan would be to cut an inspection port and apply a few layers of pre-soaked fiberglass strips around the tube, feathering up to the top deck. Is that reasonable? Also, I've not been able to find pictures of where people cut the inspection port for this type of repair, so advice on where to put it would be appreciated.

From the pictures, you can see that it is crudely sealed with silicone. There outside layer of fiberglass seems to be separating from the rest of the tube, which gives the appearance of a crack. From what I can see it's only on this outermost layer. I'm unsure what's under the rest of the silicone.

Do you think that this is worth repairing? Or should I just stick with the silicone and add more if it reopens the leak. If I were to go with a repair, I think my plan would be to cut an inspection port and apply a few layers of pre-soaked fiberglass strips around the tube, feathering up to the top deck. Is that reasonable? Also, I've not been able to find pictures of where people cut the inspection port for this type of repair, so advice on where to put it would be appreciated.

Attachments

-

PXL_20240520_073120255.jpg1 MB · Views: 93

PXL_20240520_073120255.jpg1 MB · Views: 93 -

PXL_20240520_073239960.jpg738.8 KB · Views: 77

PXL_20240520_073239960.jpg738.8 KB · Views: 77 -

PXL_20240520_073504918.jpg1 MB · Views: 78

PXL_20240520_073504918.jpg1 MB · Views: 78 -

PXL_20240520_073556073.jpg574.6 KB · Views: 62

PXL_20240520_073556073.jpg574.6 KB · Views: 62 -

PXL_20240520_073140968.jpg639.4 KB · Views: 62

PXL_20240520_073140968.jpg639.4 KB · Views: 62 -

PXL_20240520_073124239.jpg797.2 KB · Views: 66

PXL_20240520_073124239.jpg797.2 KB · Views: 66 -

PXL_20240520_073133592.jpg311.8 KB · Views: 62

PXL_20240520_073133592.jpg311.8 KB · Views: 62 -

PXL_20240520_073112018.jpg413.5 KB · Views: 53

PXL_20240520_073112018.jpg413.5 KB · Views: 53 -

PXL_20240520_073057033.jpg503.5 KB · Views: 64

PXL_20240520_073057033.jpg503.5 KB · Views: 64 -

PXL_20240520_073117483.jpg407.4 KB · Views: 53

PXL_20240520_073117483.jpg407.4 KB · Views: 53