L&VW

Well-Known Member

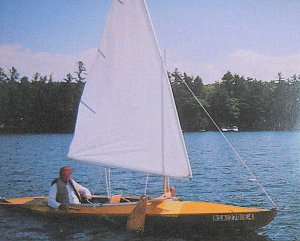

I also have a blue Folbot (wood frame). This green and yellow (metal-framed) Folbot came with a complete sail kit: A tower of power with 45 square feet of sail.You have a Folboat? Awesome! Would love to see a photo or two. Those are great examples of engineering.

As you can see, it's a long reach to bolt on a bow handle!

(Stamped, "Made in England", FWIW).

(Stamped, "Made in England", FWIW). ).

).