Tops

Mildly Thixotropic

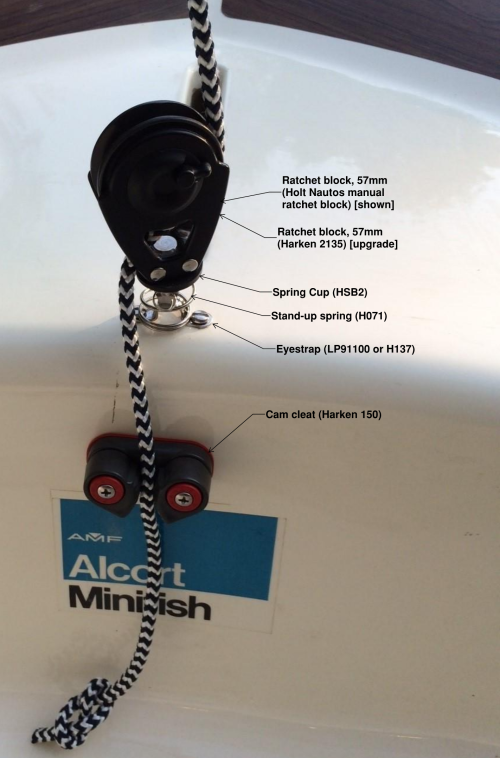

Rigging up my brand newest oldest boat, pre-AMF in styling. Boat has a block instead of halyard fairlead and eye bolts instead of eyes molded in the caps.

-I am wondering if the padeye/fairlead and camcleat shown are useful as-is, or if I'd be better off using 'the hook' or work on getting a standing block.

-Also curious about the added wooden bits, looks like something was de-mounted there. ..? No evidence of a hiking strap attempt in the rear of the footwell.

-Last but not least, is there a preferred way to safety line a 'Barrington' style daggerboard w/o holes somewhere to the boat?

I have the gooseneck and halyard more or less in the Signal Charlie 'geezer' configuration (which would be 22" gooseneck to lower boom co-joined end (tack) and 60" halyard to upper boom loose end (head).

Thanks!

-I am wondering if the padeye/fairlead and camcleat shown are useful as-is, or if I'd be better off using 'the hook' or work on getting a standing block.

-Also curious about the added wooden bits, looks like something was de-mounted there. ..? No evidence of a hiking strap attempt in the rear of the footwell.

-Last but not least, is there a preferred way to safety line a 'Barrington' style daggerboard w/o holes somewhere to the boat?

I have the gooseneck and halyard more or less in the Signal Charlie 'geezer' configuration (which would be 22" gooseneck to lower boom co-joined end (tack) and 60" halyard to upper boom loose end (head).

Thanks!

!

! Pic is after landing and backing the trailer into the recovery position. Thanks for all of the posts and collected wisdom, I appreciate being here.

Pic is after landing and backing the trailer into the recovery position. Thanks for all of the posts and collected wisdom, I appreciate being here.

Now this obviously isn't class legal but it's on my beater/beach/practice boat anyway.

Now this obviously isn't class legal but it's on my beater/beach/practice boat anyway.