rogerkallhovd

New Member

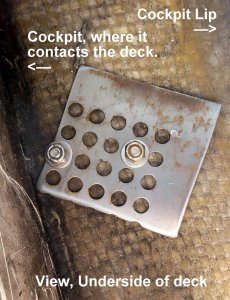

This idiot failed to turtle sunfish this winter. Cockpit and storage filled with ice. Found hull filled with water. Can't locate leak. I don't have a drain plug on deck--tho' I installed one in stern.(also installed 2 deck ports.) I know have cracks in mast hole but that stayed covered. Any suggestions as to how to locate leak? I read the "air test"--but again--have no deck drain plug--and have known cracks in mast hole. Grateful for any help.

Roger

Roger

but they're cheap and bolt-on upon receipt. Some require just the removal of a cotter pin. Try Harbor Freight. (If they are lug nuts, make sure the old lug nuts can be removed —use WD-40, "P-B Blaster" or "Kroil" to break the stubborn ones loose).

but they're cheap and bolt-on upon receipt. Some require just the removal of a cotter pin. Try Harbor Freight. (If they are lug nuts, make sure the old lug nuts can be removed —use WD-40, "P-B Blaster" or "Kroil" to break the stubborn ones loose).

The tire was then returned to its correct pressure.

The tire was then returned to its correct pressure.