Voodoo 158546

Hard hiking at the end of a 3hr race, killer

I tried a search but couldn't see anything on the forum so thought I'd just share ....

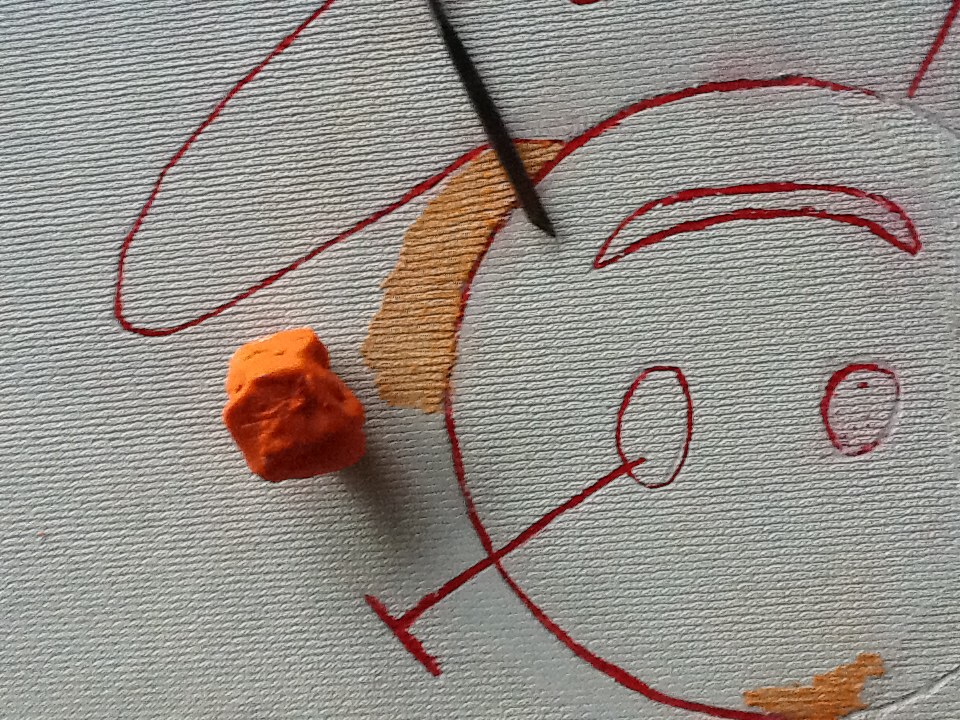

It's so simple....a lump of plasticene ( kids modelling clay ) pressed into a good bit of deck,

Carefully lifted off then roughly lined up and placed over the ding that's got a tiny amount of the correct coloured gelcoat, gentle press with something flat and leave for a couple of hours..

What looks like orange residue is merely plasticene that I haven't removed yet. I take the bulk off carefully with the sharp file and the remainder with an acetoned cloth once full cure is reached later.

If you really took your time it can come out an almost invisible blend. It's a judgement call with the amount of gelcoat you drop in the ding - way too much leaves a very distinct raised edge, too little leaves a blatant dip.

But at the end of the day it's just gelcoat, you can easily grind it off and go for it again until your happy.

It's so simple....a lump of plasticene ( kids modelling clay ) pressed into a good bit of deck,

Carefully lifted off then roughly lined up and placed over the ding that's got a tiny amount of the correct coloured gelcoat, gentle press with something flat and leave for a couple of hours..

What looks like orange residue is merely plasticene that I haven't removed yet. I take the bulk off carefully with the sharp file and the remainder with an acetoned cloth once full cure is reached later.

If you really took your time it can come out an almost invisible blend. It's a judgement call with the amount of gelcoat you drop in the ding - way too much leaves a very distinct raised edge, too little leaves a blatant dip.

But at the end of the day it's just gelcoat, you can easily grind it off and go for it again until your happy.