Laserupstateny

Member

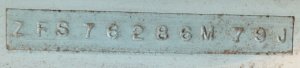

So I got a 79’ laser for free as the deck started to delaminates from being in a flood. Upon further inspection, the mast step was detached but not broken. Same with the center board trunk. I simply ground out the little resin and glue left and took the deck off of the hull. Will post more pictures later on in the project and hopefully a YouTube video. Any suggestions appreciated.