NightSailor

Captain

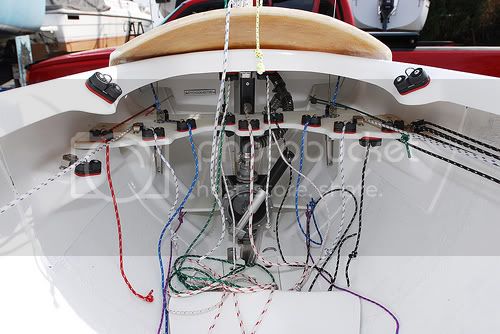

I ordered two new blocks and a nice low-stretch V100 black 3/8 inch line for the mainsheet I'm building for my racing rig. Unfortunately they sent me 7/16" line. Rather than return it, I thought I'd give it a try. I also ordered two Race-Lite swivel block--not the best blocks, but the best available for racing the Sunfish--correct me if I'm wrong. I'd much prefer some 40 or 57mm Harken carbo blocks.

Here are my new Race-Lite Swivel blocks:

The V-100 line was overkill for a Sunfish. I found a 29' length of line that was a "line tail"--the left overs from a big spool. So it didn't cost that much, but they were not very careful to list the correct size on the web site. This came from Layline.

I found a used rig from a guy locally. I'm moving my hornet sail over to that rig. I purchased two Race-Lite Sunfish blocks that will go on my best rig. All I need now is a Racing sail, outhaul and Cunningham line, and I'll be ready to do some racing. When I have $400 to blow, I'll put it towards a new sail. In the mean time, I'm making forward progress.

I decided to keep the line and go ahead and eye-splice the termination. I'm not sure if this sort of traveller shackle is legal. But if anyone wants to give me a hard time about it, I'll probably blow a fuse because I would hate to cut off a nice eye-splice like this one-I spent at least 20 minutes making it up, maybe 30 minutes.

Here are my eye-splice photos. I think every boat should use eye splices rather than ugly looking bowlines.

If you have never done an eye-splice Samson sells a nice kit for doing it. I keep it in my seabag for something to do on long voyages, albeit it is impossible to do on older lines. Soak the line in fabric softener if you want to try to splice old line--a good thing to do to all your line every year. Samson's instructions are not quite right, but if you do a few eye-splices, I think you will agree it is better to taper the core and cover before inserting it back in. Remember to put the shackle on, and be aware of where it needs to be while doing the splice, or you may end up with a nice splice and no shackle attached--I did that a few times when I was learning to splice years ago.

In any event, here is my latest splice job. It came out ok. And the line does fit into my Race-Lite blocks. Perhaps the larger diameter line will be a bit easier on the hands. I can always strip the cover off where it goes through the blocks.

Here is the other end. My whipping line was a bit large, but it was all I had available. It is a better size for larger line like on my 46. In any event, it will fit through my race lite blocks.

Splicing the Mainbrace was the largest line in a tallship. It was a hard job and was rewarded by a tot of rum. So today, splice the mainbrace, means to have a drink. I think I'll reward myself with a Corona for my work today. Ciao!

Here are my new Race-Lite Swivel blocks:

The V-100 line was overkill for a Sunfish. I found a 29' length of line that was a "line tail"--the left overs from a big spool. So it didn't cost that much, but they were not very careful to list the correct size on the web site. This came from Layline.

I found a used rig from a guy locally. I'm moving my hornet sail over to that rig. I purchased two Race-Lite Sunfish blocks that will go on my best rig. All I need now is a Racing sail, outhaul and Cunningham line, and I'll be ready to do some racing. When I have $400 to blow, I'll put it towards a new sail. In the mean time, I'm making forward progress.

I decided to keep the line and go ahead and eye-splice the termination. I'm not sure if this sort of traveller shackle is legal. But if anyone wants to give me a hard time about it, I'll probably blow a fuse because I would hate to cut off a nice eye-splice like this one-I spent at least 20 minutes making it up, maybe 30 minutes.

Here are my eye-splice photos. I think every boat should use eye splices rather than ugly looking bowlines.

If you have never done an eye-splice Samson sells a nice kit for doing it. I keep it in my seabag for something to do on long voyages, albeit it is impossible to do on older lines. Soak the line in fabric softener if you want to try to splice old line--a good thing to do to all your line every year. Samson's instructions are not quite right, but if you do a few eye-splices, I think you will agree it is better to taper the core and cover before inserting it back in. Remember to put the shackle on, and be aware of where it needs to be while doing the splice, or you may end up with a nice splice and no shackle attached--I did that a few times when I was learning to splice years ago.

In any event, here is my latest splice job. It came out ok. And the line does fit into my Race-Lite blocks. Perhaps the larger diameter line will be a bit easier on the hands. I can always strip the cover off where it goes through the blocks.

Here is the other end. My whipping line was a bit large, but it was all I had available. It is a better size for larger line like on my 46. In any event, it will fit through my race lite blocks.

Splicing the Mainbrace was the largest line in a tallship. It was a hard job and was rewarded by a tot of rum. So today, splice the mainbrace, means to have a drink. I think I'll reward myself with a Corona for my work today. Ciao!