MrBrycimus

Member

I had a capsize that turned into a turtle and then stuck in the mud on the port side. We kept sailing after getting pulled out of the mud by a power boat.

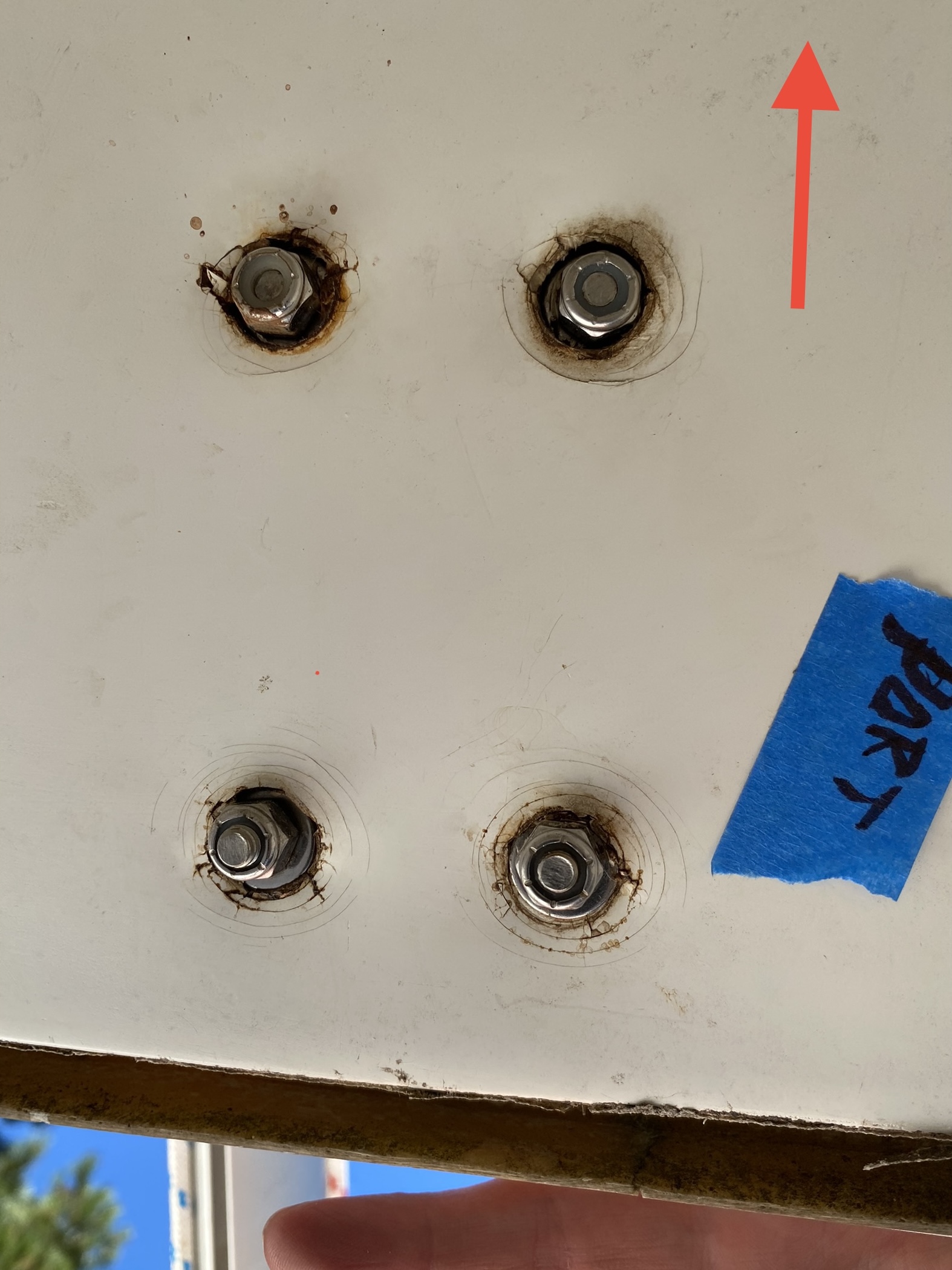

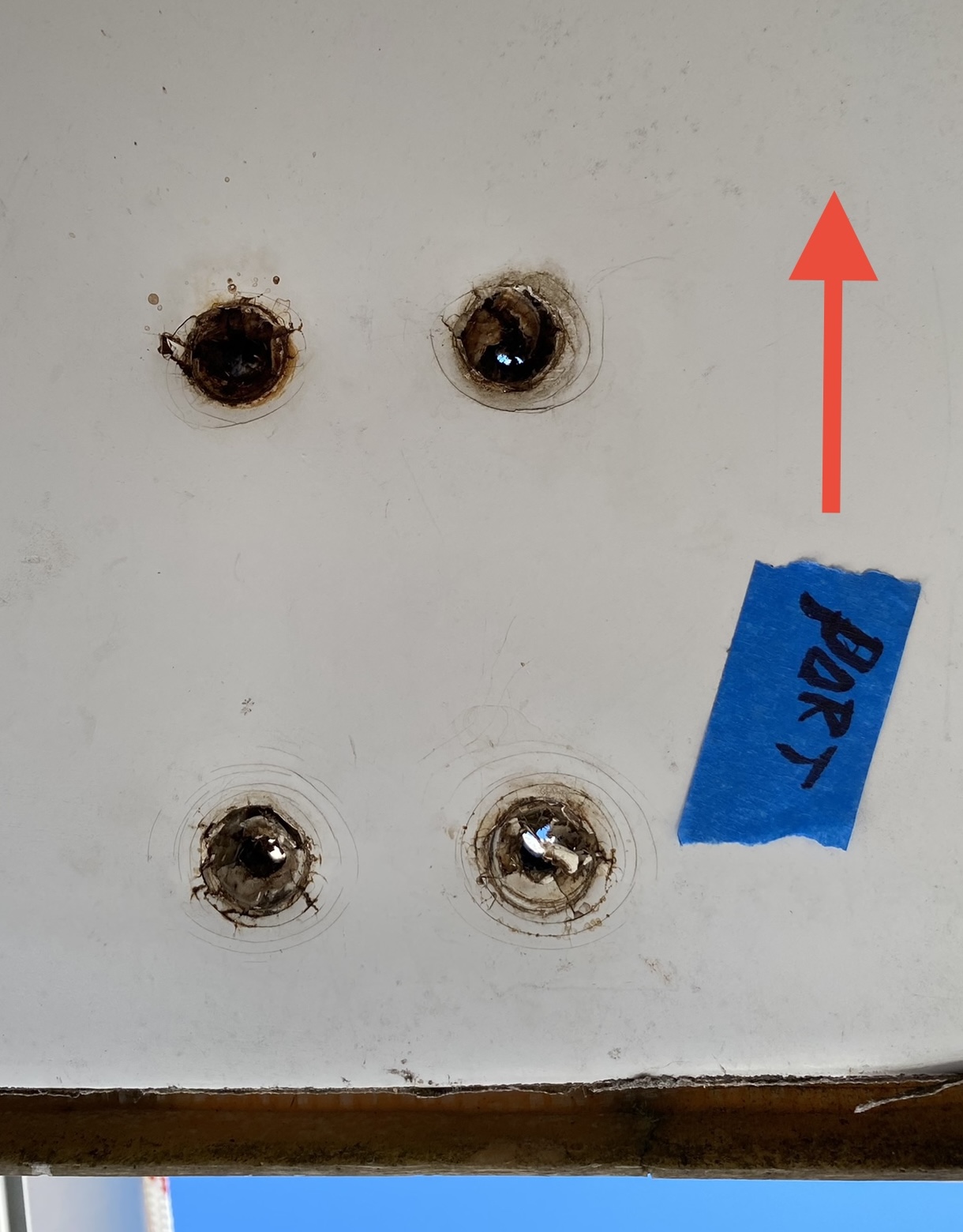

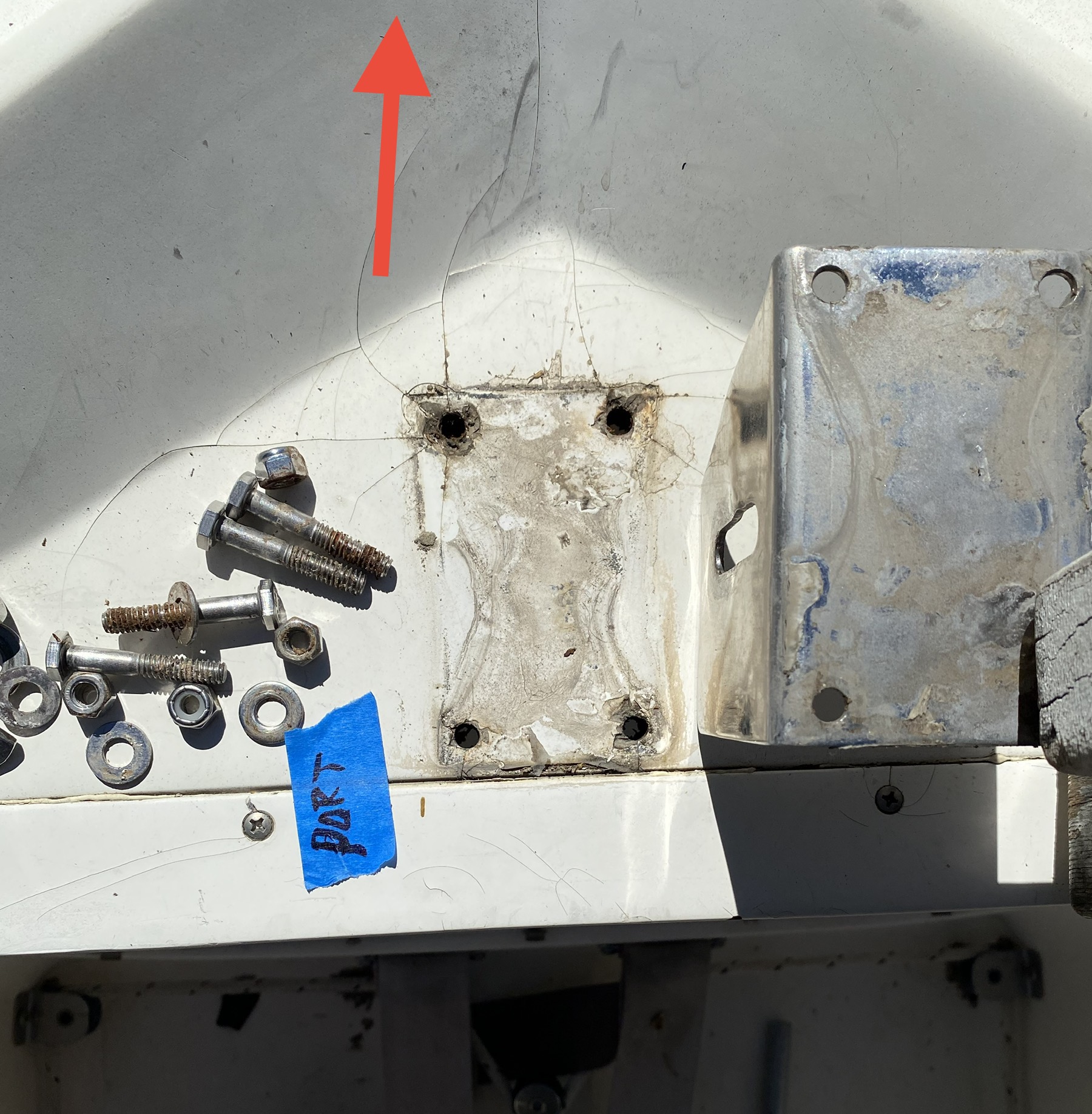

The mast step was loose after, on the port side. It looks like the washers got pulled through the plastic of the cubby in the bottom side. 1994 14.2

Questions: Does the base of the mast step need to be repaired? If so, how? If not, can I just tighten the bolts down all of the way again? Do I need to do anything on the inside of the cubby? Should there be any sealant in those holes (I saw another thread with an older model with the mast base broken/rotted)?

Previously, when I first got the boat, it had rusty bolts in those holes which I replaced with stainless hardware. However the forward side seemed to be thicker than the aft side and the nuts didn’t tighten down as far.

Thanks in advance.

1994 14.2

1994 14.2

The mast step was loose after, on the port side. It looks like the washers got pulled through the plastic of the cubby in the bottom side. 1994 14.2

Questions: Does the base of the mast step need to be repaired? If so, how? If not, can I just tighten the bolts down all of the way again? Do I need to do anything on the inside of the cubby? Should there be any sealant in those holes (I saw another thread with an older model with the mast base broken/rotted)?

Previously, when I first got the boat, it had rusty bolts in those holes which I replaced with stainless hardware. However the forward side seemed to be thicker than the aft side and the nuts didn’t tighten down as far.

Thanks in advance.