Edward Teach

New Member

Is it difficult to replace a cockpit coaming that is riveted to the deck? How do you go abount removing the old rivets?

Thanks

Edward.

Thanks

Edward.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

Is it difficult to replace a cockpit coaming that is riveted to the deck? How do you go about removing the old rivets?

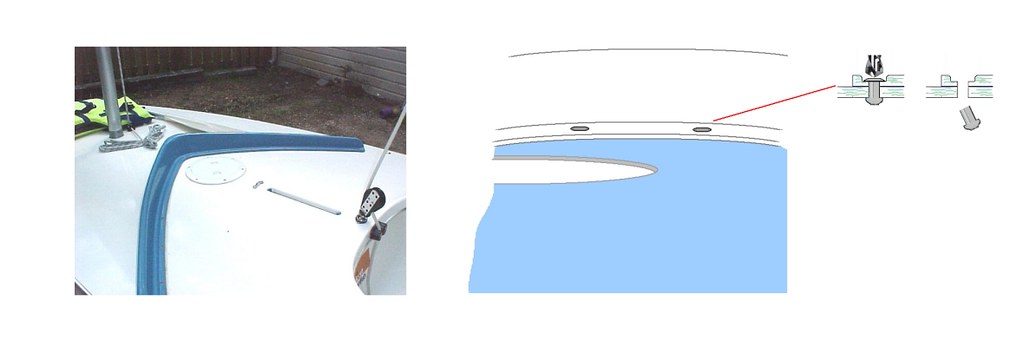

The coaming is the one deck item that does not use backing blocks.I just did a leak test this past weekend, and traced my small leak (1 & 1/2 cups an hour) to a section on the coaming. My fish is 71/72 - i.e. teak blocks underneath it all. I have screws, not rivets, attaching the coaming. Presently, the screws are spinning on their way back in. I'm fine for now, but what are the screws for this model year/period screwing into? All other forays into inside of the hull (rudder upgrade/bridle replacement) have shown that the teak blocks to be as dry as a bone. Unfortunately, I don't remember seeing any teak blocks underneath the coaming for this time period in any of the previous diagrams. Maybe I'm wrong.

If there are teak blocks underneath the coaming for this time period, and the teak has had it, I'm thinking about Marine-Tex right now as the permanent solution. I have no inspection ports in my well right now from which to go at it from that angle.

Thanks advance for any thoughts/suggestions...

Are you really getting enough water washing the deck in a day to accumulate a measurable amount inside the hull from that size leak?I ran some 3M caulking over it for now, which should last through the season. I'll pop this whole thing off next year as far as next season's project.

Also, here what some of those bubbles look like after doing a leak test...

Trouble with caulking the trim is the actual split in the hull seam could be many inches away and dirt under the trim is just channeling the leak to a point where it finally finds a path out from beneath it.There was a secondary bubble in a minor dent to a small section of the aluminum trim, which I am keeping an eye on. I rehit both the coaming and this dent with caulking this afternoon.

I noticed that too, then I read it's primarily a polyurethane, but unlike 3M 4200, they mix in a little silicone caulk to get that creamy texture.I tried the "Boatlife" brand silicone rubber today, and really liked it. Very "creamy" for silicone product

You do have to match the sealer to the job. I was just reviewing the data sheets to decide what to use to bed something that never needs to come out. What I found was...The only drawback to the 3M 5200 brand of caulking is that it is a permanent caulking, and I plan on yanking the coaming of next season and redoing it all.