Tops

Mildly Thixotropic

Started all of this back in this thread:

https://sailingforums.com/threads/padeye-and-camcleat-versus-the-hook-versus-ratchet-block.46905/page-2#post-218647

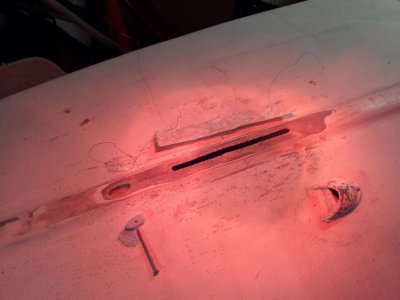

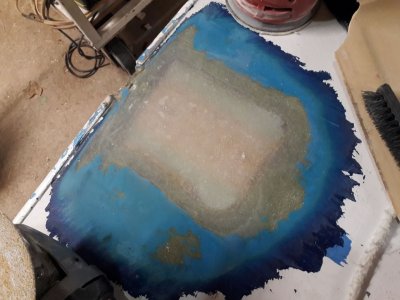

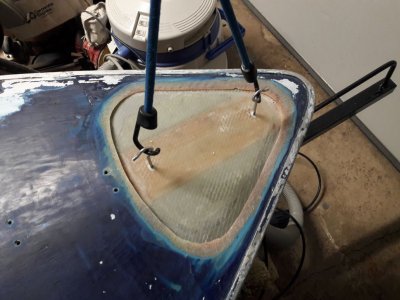

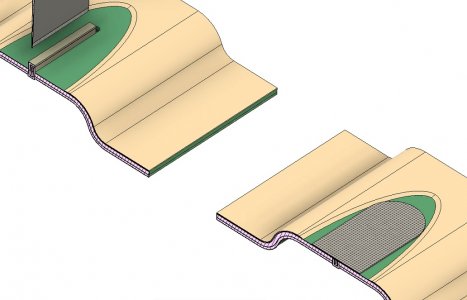

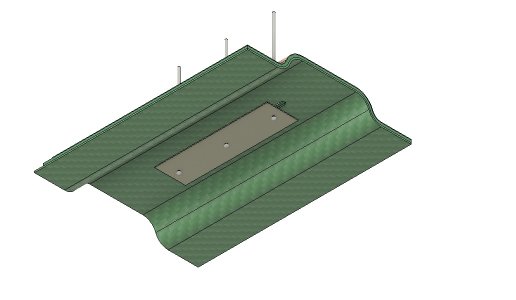

And as of tonight I am down to this, chasing the cracks caused a couple loose pieces to come out near the transom:

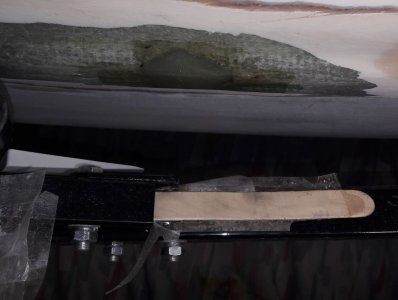

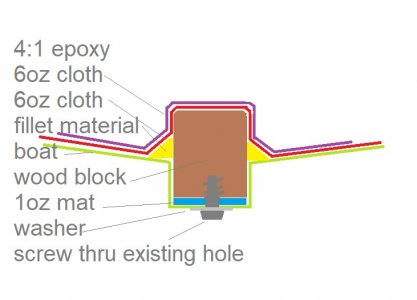

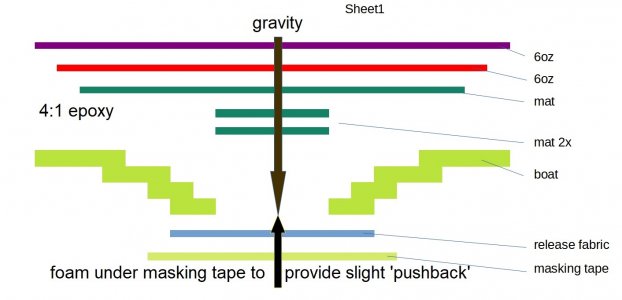

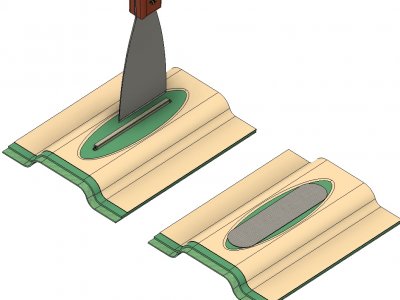

Wondering if after replacing the missing wood block (I want the option of either gudgeon system) if I should remove more of the existing glass, the stuff that looks more tan and brown instead of green.

Thanks!

https://sailingforums.com/threads/padeye-and-camcleat-versus-the-hook-versus-ratchet-block.46905/page-2#post-218647

And as of tonight I am down to this, chasing the cracks caused a couple loose pieces to come out near the transom:

Wondering if after replacing the missing wood block (I want the option of either gudgeon system) if I should remove more of the existing glass, the stuff that looks more tan and brown instead of green.

Thanks!

Only 33F (1 C) first check this morning.

Only 33F (1 C) first check this morning.