Skeglesswonder

New Member

After finding all the articles on this site about mast step repair and replacement, it got me a little scared.

I have a 1974 hull that until now, has been stored uncovered on its deck for about 10-15 years?

She is pristine with the exception of a few minor scratches and spider cracks on the hull and slight wavieness in the deck.

The cubitainers all seem to be dry and intact with a view into the drain hole.

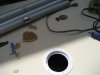

The mast step is solid with the exception of one small chip in the deck on the lip of the hole, but she doesnt eat up any water.

I let the hull soak in water for about an hour, but didnt sail it, just checking her out before the maiden voyage. She took on zero water.

I bought two inspection ports preparing for any of the worst.

Should I go ahead and drop in an inspection port by the mast step and strengthen it up?

She wont be a racer, I just wanna be able to cruise around in light to medium-heavy winds.

The rails look pretty bad so I might fork out the 80 bucks I saw for rub-rail. If anyone has a better idea, shoot them to me.

I have a 1974 hull that until now, has been stored uncovered on its deck for about 10-15 years?

She is pristine with the exception of a few minor scratches and spider cracks on the hull and slight wavieness in the deck.

The cubitainers all seem to be dry and intact with a view into the drain hole.

The mast step is solid with the exception of one small chip in the deck on the lip of the hole, but she doesnt eat up any water.

I let the hull soak in water for about an hour, but didnt sail it, just checking her out before the maiden voyage. She took on zero water.

I bought two inspection ports preparing for any of the worst.

Should I go ahead and drop in an inspection port by the mast step and strengthen it up?

She wont be a racer, I just wanna be able to cruise around in light to medium-heavy winds.

The rails look pretty bad so I might fork out the 80 bucks I saw for rub-rail. If anyone has a better idea, shoot them to me.

?

?