b10alia

New Member

Had a moderate "the water's not that deep here" two weeks ago with the daggerboard. Noticed that there was more water in the hull than there had been after previous sails, although I looked after driving home in a downpour with no gaskets on the deck plates. I picked up probably 2-3 gallons from just the rain we've had this week based on what I took out this morning.

After coming back today, I had maybe 3 gallons on board for 3 hours sailing (about double the "pre smash" rate) and noticed water dripping down from the front and rear of the daggerboard trunk while I was strapping her on the trailer. Found a chunk of what looked like old epoxy in the bilge, although this has gone "somewhere else" on the drive home. There's a pretty good crack a couple inches up into the bottom aft of the daggerboard trunk.

I don't know what the specific history is with this boat but I get the sense the keel was heavily damaged before I got it, there was a lot of "stuff" in this area. I was 14 at the time and one of my friend's dads helped me do some of the work. We put epoxy (a thin layer) with something gray in it down the length of the keel, since this was obviously pretty bad, and the idea was to give some more scrape protection. I've been wrestling with leaks in the daggerboard trunk since, though. I've gotten it pretty reasonable, the last go was with a caulk gun of 5200 and I was impressed with the results... but hoped I'd never have to repair it. I did have to spring for a small can of the "5200 remover" stuff to deal with the transom drain plug earlier this year.

Also to note: the daggerboard has never gone up and down smoothly, it takes a good hard push to go all the way down and there's enough friction that it stays up in whatever position you put it in.

So this isn't a huge issue, maybe 1 1/2" of water either side of the trunk with the boat sitting flat after sailing for a few hours. For what I do now, it's borderline OK, although I'm planning a trip in a couple of weeks that might have the boat sitting at a dock or in the water for several days.

I don't want to rip the whole bottom of the boat apart, but I think I want to try and fix this. I've never "done fiberglass" although I get the concepts and that prep is most of it.

I'm thinking about some sort of epoxy although I know people scoff at this. More 5200 would be quick but I think the problem is beyond this. I already have inspection ports either side of the trunk, about centered on it.

Pictures:

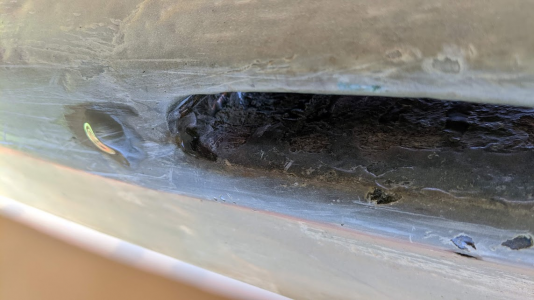

Rear of trunk on trailer, about 15 minutes after pulling out:

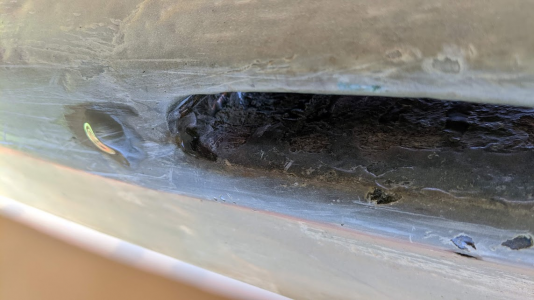

Front of trunk:

Inside trunk looking from deck, back edge

Back edge from underneath:

Front edge from top:

My 5200 repairs, port side and close-up of lower back:

Old repairs to keel area forward of daggerboard trunk:

I want to fix this "better than 5200" but the goal here is: get it to stop leaking, or leak less, permanently; and be sailable in 2wk. Preferably get the daggerboard to work properly at the same time. Have to work around the old repairs to the extent possible, and keep costs reasonable (less than $100? ish? This is boat stuff after all...)

I have (limited) weeknights and next weekend to work on it. I have some access to West System epoxies from work although I have to pay for what I use (the pumps, mainly) and getting anything we don't have in stock (we're not a boat shop) will be a bit of a hassle on the bookkeeping end. Part of why I'm thinking about epoxies.

After coming back today, I had maybe 3 gallons on board for 3 hours sailing (about double the "pre smash" rate) and noticed water dripping down from the front and rear of the daggerboard trunk while I was strapping her on the trailer. Found a chunk of what looked like old epoxy in the bilge, although this has gone "somewhere else" on the drive home. There's a pretty good crack a couple inches up into the bottom aft of the daggerboard trunk.

I don't know what the specific history is with this boat but I get the sense the keel was heavily damaged before I got it, there was a lot of "stuff" in this area. I was 14 at the time and one of my friend's dads helped me do some of the work. We put epoxy (a thin layer) with something gray in it down the length of the keel, since this was obviously pretty bad, and the idea was to give some more scrape protection. I've been wrestling with leaks in the daggerboard trunk since, though. I've gotten it pretty reasonable, the last go was with a caulk gun of 5200 and I was impressed with the results... but hoped I'd never have to repair it. I did have to spring for a small can of the "5200 remover" stuff to deal with the transom drain plug earlier this year.

Also to note: the daggerboard has never gone up and down smoothly, it takes a good hard push to go all the way down and there's enough friction that it stays up in whatever position you put it in.

So this isn't a huge issue, maybe 1 1/2" of water either side of the trunk with the boat sitting flat after sailing for a few hours. For what I do now, it's borderline OK, although I'm planning a trip in a couple of weeks that might have the boat sitting at a dock or in the water for several days.

I don't want to rip the whole bottom of the boat apart, but I think I want to try and fix this. I've never "done fiberglass" although I get the concepts and that prep is most of it.

I'm thinking about some sort of epoxy although I know people scoff at this. More 5200 would be quick but I think the problem is beyond this. I already have inspection ports either side of the trunk, about centered on it.

Pictures:

Rear of trunk on trailer, about 15 minutes after pulling out:

Front of trunk:

Inside trunk looking from deck, back edge

Back edge from underneath:

Front edge from top:

My 5200 repairs, port side and close-up of lower back:

Old repairs to keel area forward of daggerboard trunk:

I want to fix this "better than 5200" but the goal here is: get it to stop leaking, or leak less, permanently; and be sailable in 2wk. Preferably get the daggerboard to work properly at the same time. Have to work around the old repairs to the extent possible, and keep costs reasonable (less than $100? ish? This is boat stuff after all...)

I have (limited) weeknights and next weekend to work on it. I have some access to West System epoxies from work although I have to pay for what I use (the pumps, mainly) and getting anything we don't have in stock (we're not a boat shop) will be a bit of a hassle on the bookkeeping end. Part of why I'm thinking about epoxies.

". I guess I'll put that can of "5200 Begone" to work this week...

". I guess I'll put that can of "5200 Begone" to work this week...