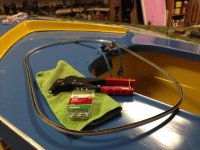

Gathering rudder parts, found a threaded backer plate.

Removed old latch plate backer block from inside the keel.

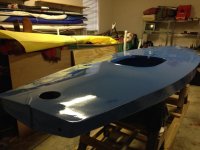

Removed cockpit trim and sanded off old paint.

Sanded old varnish off if rudder and daggerboard, put on a base coat of epoxy.

Removed old latch plate backer block from inside the keel.

Removed cockpit trim and sanded off old paint.

Sanded old varnish off if rudder and daggerboard, put on a base coat of epoxy.