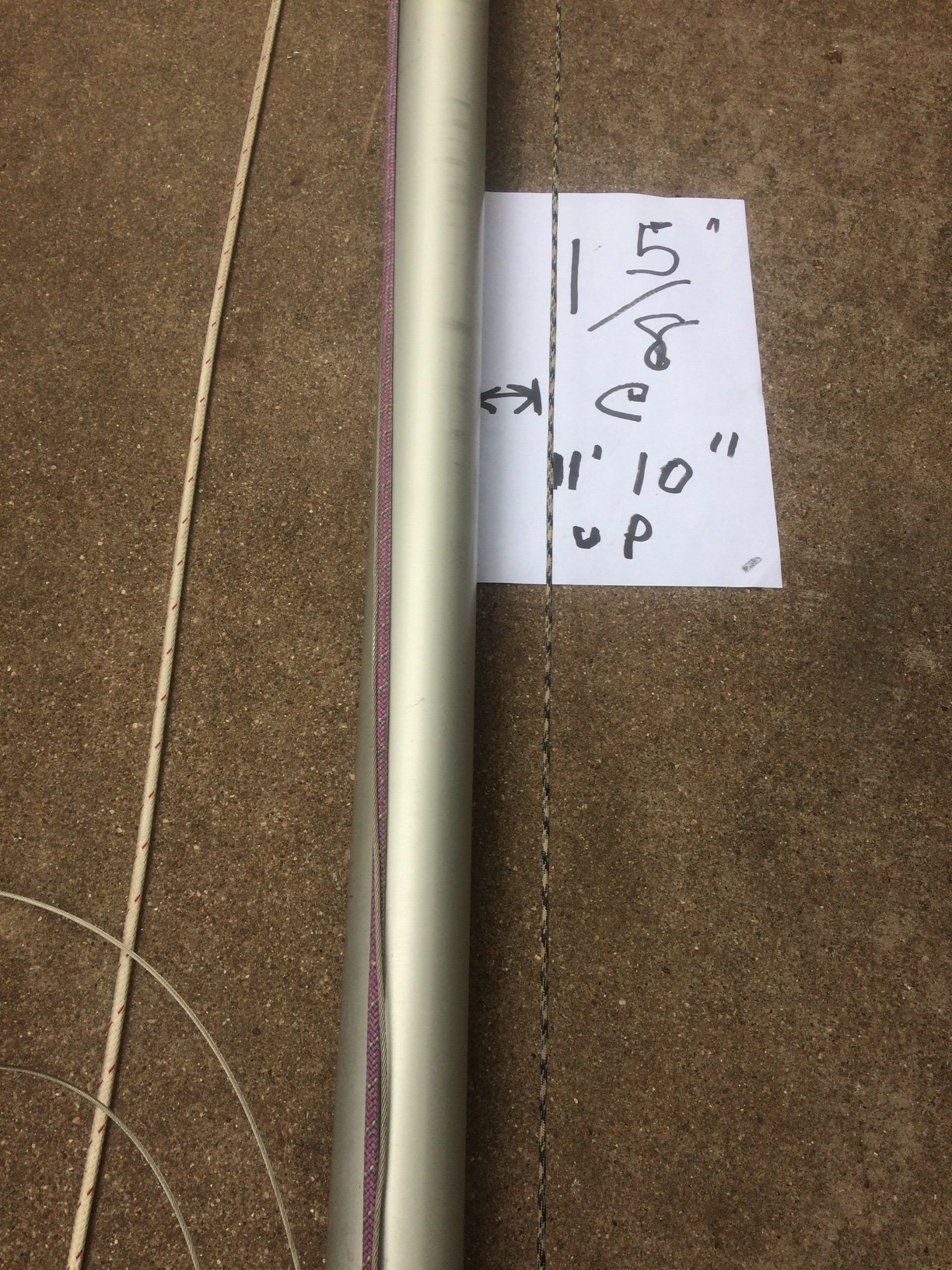

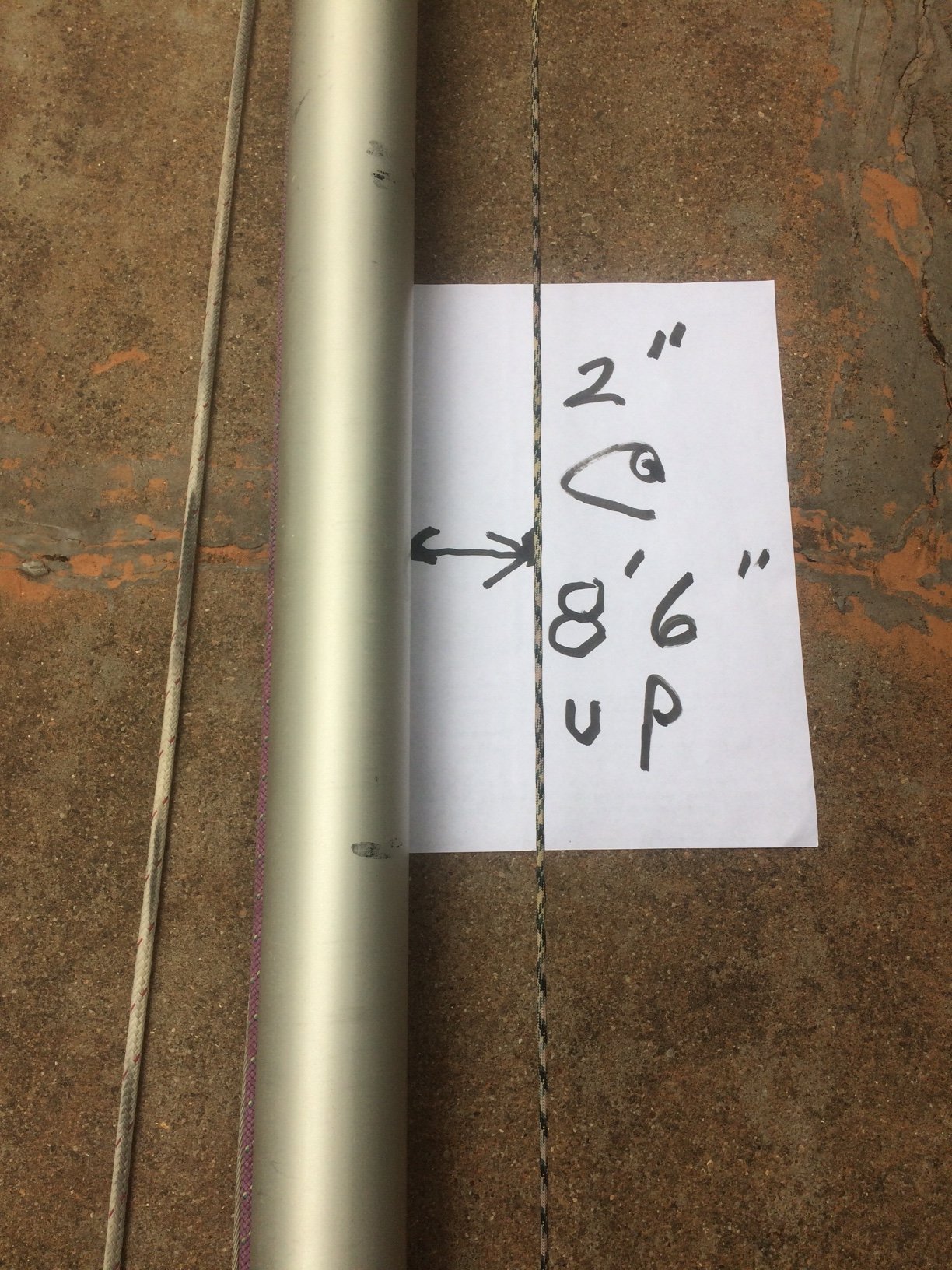

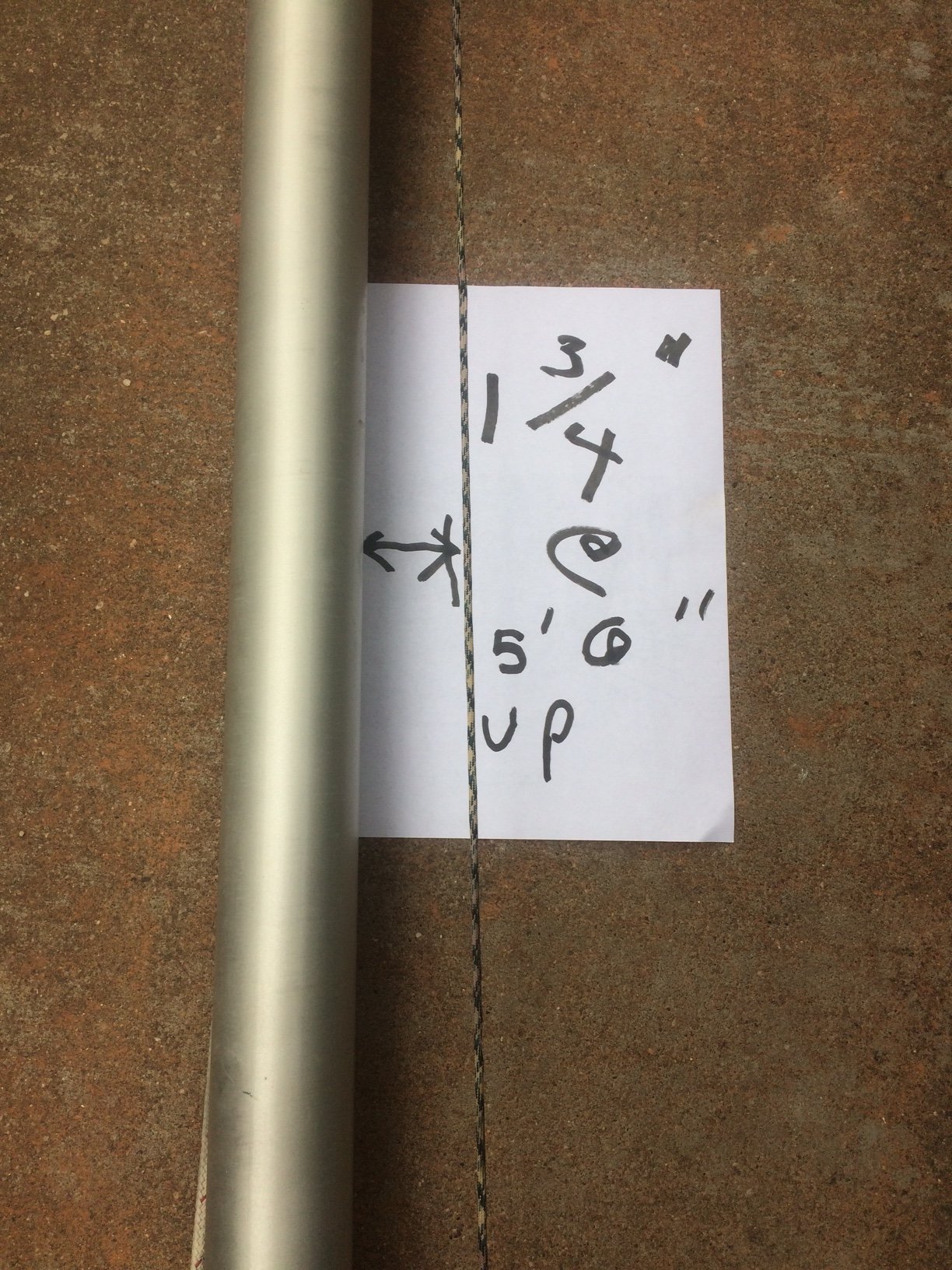

Hell all. I'm new to these boats so I apologize for my lack of knowledge. I've sailed for 30+ years in Sunfish, Laser and on sailboards but this is my forst experience with a small day sailor and stayed mast. I recently bought this boat (actually, traded a used cyclocross bike and a little cash) know that it would need some work. The primary issue is a bend in the mast. I've straightened simple round spars before but not sure how that will work for a slotted spar section like this mast. The pictures show the issue and where the bend is. I don't see any crimping, so my assumption is the the mast could possibly be straightened. Two questions: (1) Is is feasible to try to straightened the mast (either me or possibly at an automobile body shop? (2) If not, could anyone recommend a good source for a replacement spar? I'm in semi-rural Central Texas so the closest big cities would be Austin, San Antonio and Dallas/Fort Worth. Thanks in advance for your feedback