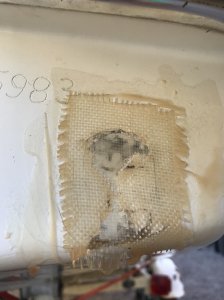

I got a holder earlier this year but this Sunfish came up locally for $600 so I couldn’t resist. One owner I think it’s a 72. Craziest thing is it came with the original manual in mint condition. It also has the cleanest bottom I have seen. Don’t think it has ever seen a rock bottom. Sails will need to be replaced soon and I will have to refinish the rudder and centerboard. However the main repair is gonna be 2 fiberglass patches. Previous owner obvious didn’t know how to use fiber glass

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Picked up a Sunfish need a few repairs before she can see the water

- Thread starter m2736185

- Start date

Nice looking boat, looks 72ish with those bow srtipes. One of the worst patch jobs we've seen, and we've seen a few. But at least it was patched and not full of water/mud.

Have fun!

Have fun!

L&VW

Well-Known Member

Especially with the trailer, that'd be a tempting buy—even for me. (And I've picked up my 6th Sunfish this weekend!I got a holder earlier this year but this Sunfish came up locally for $600 so I couldn’t resist. One owner I think it’s a 72. Craziest thing is it came with the original manual in mint condition. It also has the cleanest bottom I have seen. Don’t think it has ever seen a rock bottom. Sails will need to be replaced soon and I will have to refinish the rudder and centerboard. However the main repair is gonna be 2 fiberglass patches. Previous owner obvious didn’t know how to use fiber glass

)

)A neighbor who owns both a Sunfish and a Holder, says he prefers the Holder. "Dif'rent strokes..."

Breeze Bender

Breeze Bender

Nice find, especially if trailer was included. Is it missing the self-bailer? I had a 12’ Hobie Holder, sold it last summer. Both are great boats.

Nope self bailer is on the left if you look really close. So I am trying to get his thing in the water ASAP. I want to make sure its ready. I should have no problem refinishing the centerboard and rudder since I just had this done on the holder. There are a few chips in the hull I think I will repair with marine tex. The crack in the bucket that was poorly patched looks like it would be more trouble than its worth to repair. My main concern is that poorly patched area on the back. I don't have any experience working with fiberglass, but I think I can do a better job than that. Any suggestions on how to go about it? Should I cut around, glue some fiberglass as a backing, make a patch and then fill in the edges with thickened epoxy? Or should I make a backing, sand and start laying matte fiberglass and then filler on the top?

BTW for a dry boat should I install 1 or 2 inspection ports?

BTW for a dry boat should I install 1 or 2 inspection ports?

Webfoot1

Active Member

If the patch was put on with polyester resin you can remove it with a heat gun and a putty

knife. If that's not possible grind off the patch with a sanding disk. Cut around the edge of the damaged

area to clean up the edges. Put a inspection port on the deck and you can install a

backing plate. Search the web for how to repair fiberglass and everything else will

fall into place for you. The tub band-aid repair is like how I find Sunfish the majority

of the time. Shitty repair job but I'd just leave it as is since you can see if it starts to crack

further. I'm not sure how well the stern patch will hold up since the patch is providing close

to zero structural integrity. It will not sink but you could end up with a 300 lbs.

hull full of water. I remember a case where the hull completely filled with water.

The guy could not get it up on the beach so he just gathered up all the hardware

and left the hull to be someone else's personal reef.

knife. If that's not possible grind off the patch with a sanding disk. Cut around the edge of the damaged

area to clean up the edges. Put a inspection port on the deck and you can install a

backing plate. Search the web for how to repair fiberglass and everything else will

fall into place for you. The tub band-aid repair is like how I find Sunfish the majority

of the time. Shitty repair job but I'd just leave it as is since you can see if it starts to crack

further. I'm not sure how well the stern patch will hold up since the patch is providing close

to zero structural integrity. It will not sink but you could end up with a 300 lbs.

hull full of water. I remember a case where the hull completely filled with water.

The guy could not get it up on the beach so he just gathered up all the hardware

and left the hull to be someone else's personal reef.

L&VW

Well-Known Member

Nope self bailer is on the left if you look really close. So I am trying to get his thing in the water ASAP. I want to make sure its ready. I should have no problem refinishing the centerboard and rudder since I just had this done on the holder. There are a few chips in the hull I think I will repair with marine tex. The crack in the bucket that was poorly patched looks like it would be more trouble than its worth to repair. My main concern is that poorly patched area on the back. I don't have any experience working with fiberglass, but I think I can do a better job than that. Any suggestions on how to go about it? Should I cut around, glue some fiberglass as a backing, make a patch and then fill in the edges with thickened epoxy? Or should I make a backing, sand and start laying matte fiberglass and then filler on the top?

BTW for a dry boat should I install 1 or 2 inspection ports?

1) If you were to sell it, I (as a buyer) would be most impressed with a 130-pound Sunfish with no inspection ports.

2) I'd leave the patch in the bottom of the cockpit, but maybe sand it flat (using a block of wood), and spray-paint it white. Other cracks are inevitable—check the other side of the hull, underneath. A "hit" outside will produce tub cracks like yours, inside. The outside may show no damage, be intact, but feel like a weak spot when pressed; still, I'd leave it alone.

3) The patch on the transom may (only) be covering a major chip in the hard finish coat of gelcoat. I'd sand it flat to match the transom—press to see if it's worse—and, if it's not spray-paint it to match.

Last edited:

Breeze Bender

Breeze Bender

I wouldn’t add inspection ports unless the boat is overweight (2 ports if very heavy) or if you have to make structural or hardware repairs- or if you’re upgrading to newer rudder. Use a sander to grind out the old patch until the hole on the side is cleaned up. I don’t think you’ll need a backing plate. Just watch a couple YouTube videos and search the forum- you can fix that! After you patch and before you cut any holes do a leak test. Kent has a great video on that- just search YouTube ‘Sunfish leak test’. Many people skip this important step and never find the tiny crack under the trim (or wherever) that allows many gallons of water to enter the hull.

So I have looked at many fiberglass videos and they all make it seem easier than it is. I think the easiest method I have seen it the patch where you use a screw to make the backing and then create an exact patch and sand. My only question is what type of fiberglass should I use and how many layers would be equal to the hull thickness of the sunfish

Webfoot1

Active Member

Not sure what you mean by exact patch. You have to grind away the gelcoat around the damaged area

to an area the is about 12 percent the total of the damaged area. The good thing about fiberglass is that

it's very easy to repair compared to other materials. Most of the time is spent sanding and filling.

You want 3 layers of fiberglass (mat - cloth - mat- cloth - mat - cloth). People use all sorts of stuff

for backing plates but I make mine out of fiberglass. Lay out a sheet of waxed-paper and lay down

a couple layer of mat/cloth. If you mean '"exact patch" by using the '"Shore Line Method" you can

also make the fiberglass battens the same way. Personally I'm not a fan of polyester resin although

you can get it cheap in Bondo brand from the auto parts store. I think most of us here use something

like West Epoxy which is worth the extra cost.

If you want to experiment first see if you can find something like a fiberglass cafeteria tray to mess

with. Or a junk fiberglass canoe. All foam picnic coolers are cheap and good for practice.

to an area the is about 12 percent the total of the damaged area. The good thing about fiberglass is that

it's very easy to repair compared to other materials. Most of the time is spent sanding and filling.

You want 3 layers of fiberglass (mat - cloth - mat- cloth - mat - cloth). People use all sorts of stuff

for backing plates but I make mine out of fiberglass. Lay out a sheet of waxed-paper and lay down

a couple layer of mat/cloth. If you mean '"exact patch" by using the '"Shore Line Method" you can

also make the fiberglass battens the same way. Personally I'm not a fan of polyester resin although

you can get it cheap in Bondo brand from the auto parts store. I think most of us here use something

like West Epoxy which is worth the extra cost.

If you want to experiment first see if you can find something like a fiberglass cafeteria tray to mess

with. Or a junk fiberglass canoe. All foam picnic coolers are cheap and good for practice.

I have left over epoxy from my rudder/centerboard restoration on my holder. This is the method I was referring to

This is the cloth I was going to purchase

Fiberglass Cloth - 10 Ounce

and

Fiberglass Mat | Chopped Strand Mat | CSM

This is the epoxy I currently have

Fiberglass Mat | Chopped Strand Mat | CSM

This is the cloth I was going to purchase

Fiberglass Cloth - 10 Ounce

and

Fiberglass Mat | Chopped Strand Mat | CSM

This is the epoxy I currently have

Fiberglass Mat | Chopped Strand Mat | CSM

Webfoot1

Active Member

Sunfish is not sandwich core but just woven roving and resin. Opposite side the backing plate

you'll bevel the 12% bonding area down to the hole edge. Each of you're 3 matt/cloth groups

will be bigger than the one under it so it will sort of be like building a inverted pyramid over

the damaged area. You have a couple options to making it easier to get at the back of the

repair. You can put in a inspection plate or remove the trim and pop the rear deck. If

the damage extends past the transom and under to the bottom of the hull I say pop

the deck. Less than that I'd just install the standard inspection port on the rear deck at

the standard location. I think you have a pretty good handle on it. You just need

to pick a fiberglass filler of choice. I like micro balloons but other fillers are faster.

you'll bevel the 12% bonding area down to the hole edge. Each of you're 3 matt/cloth groups

will be bigger than the one under it so it will sort of be like building a inverted pyramid over

the damaged area. You have a couple options to making it easier to get at the back of the

repair. You can put in a inspection plate or remove the trim and pop the rear deck. If

the damage extends past the transom and under to the bottom of the hull I say pop

the deck. Less than that I'd just install the standard inspection port on the rear deck at

the standard location. I think you have a pretty good handle on it. You just need

to pick a fiberglass filler of choice. I like micro balloons but other fillers are faster.

Webfoot1: Are you kidding? I can barley handle this little patch job. I wouldn't even think of popping the rear deck. BTW thanks for the tip with the heat gun. The fiberglass tape that was used came right off. Now that I can see what is under I am considering just filling it, but I guess the correct way would be to use fiberglass?

So the material I linked to above should be sufficient? I want to order so I can get this thing in the water asap. A lot of the youtube videos I watches suggested biaxial fiberglass.

So the material I linked to above should be sufficient? I want to order so I can get this thing in the water asap. A lot of the youtube videos I watches suggested biaxial fiberglass.

Attachments

Webfoot1

Active Member

Grind down to the fiberglass so you can see the extent of the damage, i.e. grind off all gelcoat in damaged area till you have just clear fiberglass. If there are no spider webs/cracks in the fiberglass you may just have a sand/fill/re-gel coat project. I'm thinking I can see some cracks/gaps. If so you have two options, grind down to compromised

fiberglass and lay glass over it which is the not-so-correct way but works on Sunfish or the correct way which is to remove the damaged area. For experience the may help with more valuable boats in the future taking the extra time to do it correctly is probably best. If you go with filler over cracks you'll just end up with cracked filler.

Your shopping list is good, just need a fiberglass filler or micro-balloons or such.

I would not worry about biaxial fiberglass unless you have compound curves. Would be good for something like a damaged bow. What you have listed with easily conform.

fiberglass and lay glass over it which is the not-so-correct way but works on Sunfish or the correct way which is to remove the damaged area. For experience the may help with more valuable boats in the future taking the extra time to do it correctly is probably best. If you go with filler over cracks you'll just end up with cracked filler.

Your shopping list is good, just need a fiberglass filler or micro-balloons or such.

I would not worry about biaxial fiberglass unless you have compound curves. Would be good for something like a damaged bow. What you have listed with easily conform.

L&VW

Well-Known Member

WoW!  That so-called "repair" started with rolled-up cardboard?

That so-called "repair" started with rolled-up cardboard?  'Looks like it got "speared", perhaps backing into a sawed-off limb while on the trailer? (I know about backing into things!)

'Looks like it got "speared", perhaps backing into a sawed-off limb while on the trailer? (I know about backing into things!)  Thin cracks in the gelcoat point to a "heavy-hit".

Thin cracks in the gelcoat point to a "heavy-hit".

Long-term, that needs a repair as discussed by member Webfoot1; however, grinding down to "fresh filler" and the use of your present supply of Marine-Tex would get you out on the water tomorrow. Heck, I've satisfied my sailing "need" using duck-tape to substitute for a bailer!

My "days-old" Sunfish #6 is missing hardware—is hurricane-damaged—and is also missing both transom corners. I don't want to invest any "work" in it, but use it for research Maybe, cut out sections for "backing plates" to sell or use for my own repairs.

Maybe, cut out sections for "backing plates" to sell or use for my own repairs.

The transom appears to be a more complex "build" than at first glance. (Meaning, it's not a simple corner, like Sunfish chines are). This is the left "corner", damaged during Hurricane Irma:

(Meaning, it's not a simple corner, like Sunfish chines are). This is the left "corner", damaged during Hurricane Irma:

That so-called "repair" started with rolled-up cardboard?

That so-called "repair" started with rolled-up cardboard?  'Looks like it got "speared", perhaps backing into a sawed-off limb while on the trailer? (I know about backing into things!)

'Looks like it got "speared", perhaps backing into a sawed-off limb while on the trailer? (I know about backing into things!)  Thin cracks in the gelcoat point to a "heavy-hit".

Thin cracks in the gelcoat point to a "heavy-hit".

Long-term, that needs a repair as discussed by member Webfoot1; however, grinding down to "fresh filler" and the use of your present supply of Marine-Tex would get you out on the water tomorrow. Heck, I've satisfied my sailing "need" using duck-tape to substitute for a bailer!

My "days-old" Sunfish #6 is missing hardware—is hurricane-damaged—and is also missing both transom corners. I don't want to invest any "work" in it, but use it for research

Maybe, cut out sections for "backing plates" to sell or use for my own repairs.

Maybe, cut out sections for "backing plates" to sell or use for my own repairs. The transom appears to be a more complex "build" than at first glance.

(Meaning, it's not a simple corner, like Sunfish chines are). This is the left "corner", damaged during Hurricane Irma:

(Meaning, it's not a simple corner, like Sunfish chines are). This is the left "corner", damaged during Hurricane Irma:I got the dremel out today and it was cutting into boat like butter I had to slow it down. Looks like there is a small gap here and there. I suppose the best way would be to just cut the area out place a blind hole patch and then lay the glass? Since its so close to the bottom I guess I should sand off the gelcoat about an inch under so the last piece of glass can extend to the bottom about an inch or so?

Attachments

Webfoot1

Active Member

Well, thats the trick. Tapering slightly over the bottom lip of the transom

without destroying the lip. If the lip is ground away then you have to bend

the backing patch. Really does not look like you will have to go more than

just around the corner. You want the taper ground so your patch is flush when done. If the lip is lost it should not be too hard to bend a thin fiberglass backer around the corner. Consider this, if you use a fiberglass backer first, maybe two or three layers applied in three sessions, you can then grind instead of cut away the damaged area. This will leave the backer retaining the shape of transom lip you can layup over. This means you need to at least have a inspection port to get inside the damaged area. Probably the best way to assure a invisible repair for a first time attempt. A dremel does go through fiberglass like nothing is there. A three layer backing plate would provide a little protection against a over enthusiastic dremel. You are of course dealing with a hull made out of one layer of woven roving. Pretty thin stuff. When I do keel repair I end up with a three layer backer and a three layer patch. Maybe it's overkill but it will not fail short of a major disaster, like a tree falling on it.

without destroying the lip. If the lip is ground away then you have to bend

the backing patch. Really does not look like you will have to go more than

just around the corner. You want the taper ground so your patch is flush when done. If the lip is lost it should not be too hard to bend a thin fiberglass backer around the corner. Consider this, if you use a fiberglass backer first, maybe two or three layers applied in three sessions, you can then grind instead of cut away the damaged area. This will leave the backer retaining the shape of transom lip you can layup over. This means you need to at least have a inspection port to get inside the damaged area. Probably the best way to assure a invisible repair for a first time attempt. A dremel does go through fiberglass like nothing is there. A three layer backing plate would provide a little protection against a over enthusiastic dremel. You are of course dealing with a hull made out of one layer of woven roving. Pretty thin stuff. When I do keel repair I end up with a three layer backer and a three layer patch. Maybe it's overkill but it will not fail short of a major disaster, like a tree falling on it.

Last edited by a moderator:

Well I was trying to avoid cutting into the hull since the boat is otherwise in such good condition and has been dry, but I guess it doesn't hurt to just install 2 inspection ports while I'm at it. The hull is gonna get some water in it regardless. At least I can dry it out each time. Considering I'm in NM this should be an easy to accomplish. Once I install inspection port will there be foam to cut away to get to the hole?

Light and variable winds: You were right. Previous owner backed into another trailer.

Light and variable winds: You were right. Previous owner backed into another trailer.

Webfoot1

Active Member

You'll have to remove a bit of the foam block in the stern but that's not

a problem. You will not have to replace it and there is plenty left to

support the deck. The ports are well worth it and you can store your

lines and junk like keys and wallet in them. They far outweigh the

"Swiss Cheese" look some people worry about.

a problem. You will not have to replace it and there is plenty left to

support the deck. The ports are well worth it and you can store your

lines and junk like keys and wallet in them. They far outweigh the

"Swiss Cheese" look some people worry about.

Breeze Bender

Breeze Bender

Don’t forget to do that leak test! I’d do it before cutting any ports. Is the boat very heavy?

Webfoot1

Active Member

The chance of a mid 70's Sunfish not leaking is small to none. They were never

expected to be in service for so long. I just use a 50 cc syringe to suck the water

out after sailing. With both ports open the deck heats up in the Sun and convection drys

out the hull.

expected to be in service for so long. I just use a 50 cc syringe to suck the water

out after sailing. With both ports open the deck heats up in the Sun and convection drys

out the hull.

L&VW

Well-Known Member

If convection is too slow, get a 4-inch muffin fan:The chance of a mid 70's Sunfish not leaking is small to none. They were never expected to be in service for so long. I just use a 50 cc syringe to suck the water out after sailing. With both ports open the deck heats up in the Sun and convection dries out the hull.

Getting ready to start repair | SailingForums.com

(Quiet, <$10, effective, extremely low draw of house current, last forever). ☆☆☆☆☆

I was on the fence about installing ports, but I suppose you are right. Odds are its getting water in there. I cut the repair out and placed the backing patch today. I was able to do so without a port. Unfortunately I only had the epoxy I used to refinish my wood (the Jamestown 1:2). I am sure it will be enough to hold. West system epoxy and glass is coming on Tuesday so I was hoping to have it ready to finish the repair and get this damn thing in the water over the weekend. Another thing I noticed inside the bucket I am questioning if its water right or not. I am going to do a leak test once this epoxy cures.

Attachments

L&VW

Well-Known Member

I think what you are calling the "bucket", is what we'd call the "cubby". While there may be some porosity at the deck seam, it's unlikely to leak significant water—even if you should "turn turtle". A leak at the cockpit seam is another story...

L&VW

Well-Known Member

Nicely done, so far. I'd be tempted to insert a "curb feeler", and send a picture of it to the previous owner.  (Maybe I'm the only member to remember "curb feelers")?

(Maybe I'm the only member to remember "curb feelers")?

When I wanted a permanent bow handle, I ran bolts through the new one. Using epoxy made this repair stronger than the hull.

(Maybe I'm the only member to remember "curb feelers")?

(Maybe I'm the only member to remember "curb feelers")?

When I wanted a permanent bow handle, I ran bolts through the new one. Using epoxy made this repair stronger than the hull.

I think she might see water this weekend. Winds are gonna be 15...a little more than I wanted for my first trip. Did a total of 4 layers of fiberglass and covered with marine tex. Not exactly seamless, but it seems pretty strong and water proof. I kept sanding to make it more level, but the more I sanded the worse it started looking so I just stopped. Refinishing the wood and ill have to make a temp tiller extension but looks like she is good to go. Leak test didn't find any leaks, Only where the hole was.