Breeze Bender

Breeze Bender

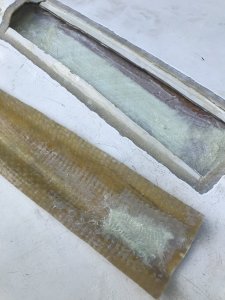

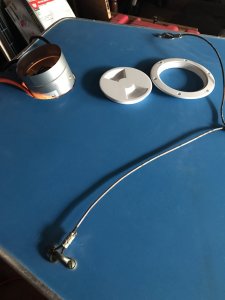

I’m thinking this crack, which extends almost the length of the cockpit, will need a blind patch from the inside of the hull. Previous owner attempted to repair with what looks like Marine Tex but that was obviously unsuccessful. I’ve also got a hole on the keel. The hole in the keel will be cleaned up, filed, etc, then I can easily install a backer. The cockpit crack is tougher. Do I have to make it bigger to get a patch behind it? Or cut out hole in the keel (Shoreline method) and access bottom of cockpit that way? Thanks for your thoughts.

The feeling was, of pulling out soggy sponges!

The feeling was, of pulling out soggy sponges!