pehare

Member

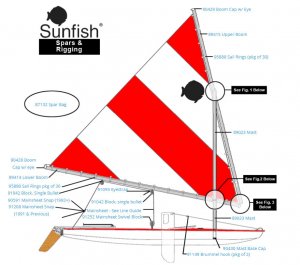

Hello...I just purchased a nice '77 Sunfish. Please pardon the clueless questions. The previous owner raced it and has the sail rigged low so the gooseneck is about 8" off the front deck and the boom is fairly horizontal with the deck which isn't going to leave me much room in the cockpit. I'm taking her out tomorrow for the first time and wondering how to properly adjust so I have more room. Or, should I take her out and see how it goes? I did sail a Laser a few times 40 yrs ago so I'm not completely green.

Also, adjacent to the Halyard Bullseye Fairlead on the starboard side of the Fairlead there is a stress crack in the fiberglass. There is an inspection port aft of there on the deck but my arm can't reach far enough forward to reach inside to feel what's going on. Does the Fairlead have a wood block under the deck? This is worry some so any ideas there?

Otherwise the boat is in nice shape...dry and light - a real beauty for it's age. Thank you for any input...

Also, adjacent to the Halyard Bullseye Fairlead on the starboard side of the Fairlead there is a stress crack in the fiberglass. There is an inspection port aft of there on the deck but my arm can't reach far enough forward to reach inside to feel what's going on. Does the Fairlead have a wood block under the deck? This is worry some so any ideas there?

Otherwise the boat is in nice shape...dry and light - a real beauty for it's age. Thank you for any input...