Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mast Horn Cleat

- Thread starter IrishAyes

- Start date

-

- Tags

- rigging help 14.2

Make sure the rig is still secured to the hull somehow, other wise the mast, spars and sail can fall our during a capsize.

L&VW

Well-Known Member

I see that many newer Sunfish have a horn cleat on the starboard side of the mast. My older rig does not have one. Is that something I need to add?? If so, what is the best way for me to attach it to the mast? Aluminum Pop Rivets? Screws?

Having had a mast snap at 14" above the deck, I hesitate to drill holes in the mast. Has anyone used 3M 5200 adhesive for this purpose?

Some find it difficult to work with.

sailcraftri

Well-Known Member

I never thought of using 5200 as sun block.

tag

my2fish

I used screws, and like JohnCT, put it as high up off the deck as possible. I used the 3M 4200 sealant behind the cleat, and fastened it on with #10 stainless steel sheet metal screws – I had to pre-drill the mast with small pilot holes.

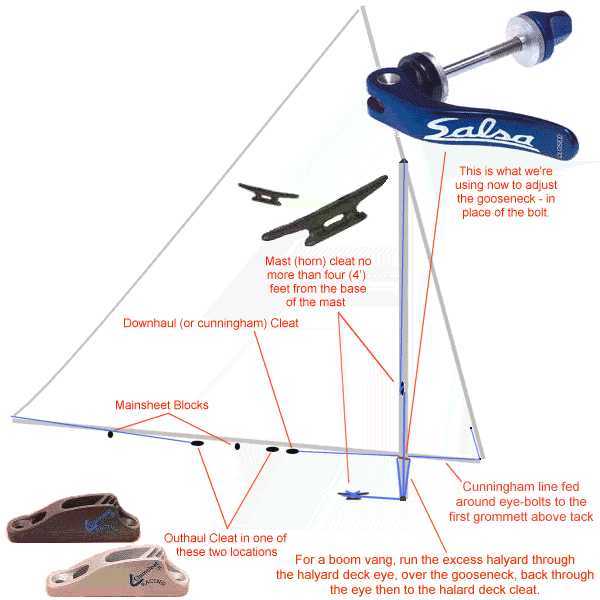

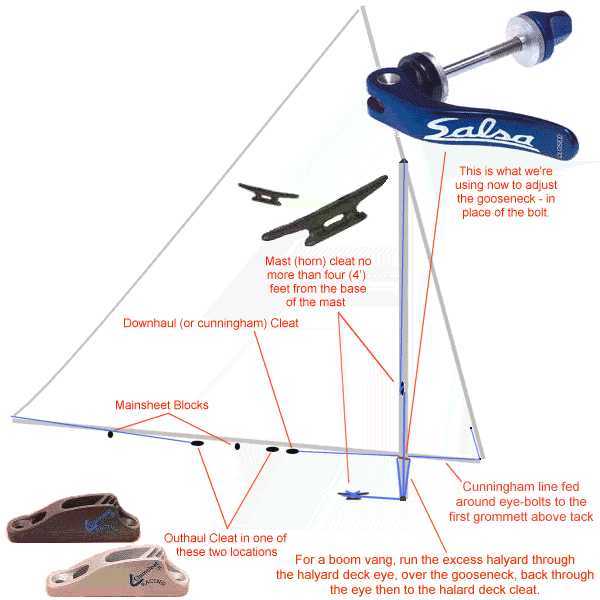

this picture is a good diagram of where to put it, as well as other rigging information.

this picture is a good diagram of where to put it, as well as other rigging information.

Hey Andy, that must have been the guy 5200ing the splashguard to your boat!

andyatos

Well-Known Member

By golly, you're right! I thought that dude looked familiar.Hey Andy, that must have been the guy 5200ing the splashguard to your boat!

- Andy

Mashmaster

Active Member

did you use a 3" nylon horn cleat?

tag

my2fish

I used the 3" nylon horn cleat from Intensity Sails for my Minifish... but I don't really like it. it's a bit too small, honestly, and even feels a tad cheap.did you use a 3" nylon horn cleat?

the "official" Sunfish horn cleat is 3 3/4" and aluminum, and I like it much better - that's what I have on my Sunfish mast. it just costs more than the nylon one.

Sunfish 91070 Sailboat Supplies, Engine Parts and Boat Parts

mixmkr

Well-Known Member

If you put the cleat too high, you won't be able to reach it in waist deep water. You might consider that too. Lastly I think two properly drilled holes with screws will not be the weak area in a Sunfish mast.

Mashmaster

Active Member

How did it snap?I just saw a mast snap exactly where the horn cleat was. It was a bit too low in my opinion...

Charles Howard

Well-Known Member

Was the mast used in salt water?

beldar boathead

Married to Primat Boathead

If you are going to race check the Sunfish rules. There is some type of rule about where the mast cleat can go.a lot of breeze and probably just old. However, it did snap at the exact place where the horn cleat was. I agree with someone above that said it should be at least 4 feet off the deck...

As beldar says

One cleat of any type may be installed on the mast not more than four (4‟) feet from the base, for cleating the line used to tie the „Jens Rig‟ (Ref. Rule 3.7.3). It may also be used to cleat the halyard. If utilized, there must be some means to securely attach the rig to the hull using the end of the halyard.

One cleat of any type may be installed on the mast not more than four (4‟) feet from the base, for cleating the line used to tie the „Jens Rig‟ (Ref. Rule 3.7.3). It may also be used to cleat the halyard. If utilized, there must be some means to securely attach the rig to the hull using the end of the halyard.

L&VW

Well-Known Member

Any "insult" to the mast can be expected to cause trouble.a lot of breeze and probably just old. However, it did snap at the exact place where the horn cleat was. I agree with someone above that said it should be at least 4 feet off the deck...

My mast broke in a very strong wind; however, I couldn't find any significant corrosion at the break site. (No different there, than the rest of the mast). I suspect that an overloaded mast can break at roughly the same location on any Sunfish. If an "insult" (corrosion- or drilled-hole) is added, expect that hole to be the site of a break. Higher cleats would be safer for the mast.

Later Sunfish were equipped with an internal sleeve, which can be retrofitted.

(This mast had no cleat).

.

L&VW

Well-Known Member

'Wuz wondering about using an adhesive to bond the cleat to the mast. Is 3M's 5200 up to the job? Went here and found a lot of choices available:

Joining metal with adhesives

Aluminum forms a protective oxide finish within seconds of "roughing-up" the surface. You'd have to put the adhesive on immediately after preparation—then slap the cleat on the mast and clamp it. Just remember to align the cleat with the mast cap.

The idea being, to eliminate drilling holes altogether. Though I'd be tempted to wait 'til it's set, then drill one hole for a pop-rivet. The innovative "aDP" pop-rivet might have a future here. ADP Rivets - Colored Blind Rivets Made in the USA (Makes its own backing-plate!)

It wouldn't hurt to wrap a piece of coarse sandpaper around the mast, and hand-form the cleat base into a matching concave shape. I have some 24-grit sandpaper. (Need gloves to handle it!)

(Need gloves to handle it!)

I'll be back at my three Sunfish "haven" in two weeks and might give an adhesive a try.

.

Joining metal with adhesives

Aluminum forms a protective oxide finish within seconds of "roughing-up" the surface. You'd have to put the adhesive on immediately after preparation—then slap the cleat on the mast and clamp it. Just remember to align the cleat with the mast cap.

The idea being, to eliminate drilling holes altogether. Though I'd be tempted to wait 'til it's set, then drill one hole for a pop-rivet. The innovative "aDP" pop-rivet might have a future here. ADP Rivets - Colored Blind Rivets Made in the USA (Makes its own backing-plate!)

It wouldn't hurt to wrap a piece of coarse sandpaper around the mast, and hand-form the cleat base into a matching concave shape. I have some 24-grit sandpaper.

(Need gloves to handle it!)

(Need gloves to handle it!)I'll be back at my three Sunfish "haven" in two weeks and might give an adhesive a try.

.

tag

my2fish

[puts on my day job structural engineer hat]

drilling a small pilot hole should not significantly weaken the mast cross section. traditional checks on the member's gross, or full, cross section are against the material yield strength, and net section checks are against the material rupture strength (often 15% higher, or more, than yield strength) - so while the pilot hole does cause a small loss of net section, the higher rupture strength compensates for it.

if failures are occurring at that location, I'd hazard to guess it is primarily due to years of corrosion, not the small loss of net section from the pilot hole. the bending and shear stresses on the mast will be highest down near the deck, so that would mean the higher you mount the mast cleat, the better. granted, the 48" limit makes it difficult to reach the cleat to de-rig if you're standing in the water.

drilling a small pilot hole should not significantly weaken the mast cross section. traditional checks on the member's gross, or full, cross section are against the material yield strength, and net section checks are against the material rupture strength (often 15% higher, or more, than yield strength) - so while the pilot hole does cause a small loss of net section, the higher rupture strength compensates for it.

if failures are occurring at that location, I'd hazard to guess it is primarily due to years of corrosion, not the small loss of net section from the pilot hole. the bending and shear stresses on the mast will be highest down near the deck, so that would mean the higher you mount the mast cleat, the better. granted, the 48" limit makes it difficult to reach the cleat to de-rig if you're standing in the water.

Alan S. Glos

Well-Known Member

Other advantages of the mast cleat: The mast cleat reduces the down-thrust of the mast and, I believe, makes the boat easier to tack in light air. It also reduces the tendency of the the base of the mast to grind through the bottom of the mast hole and cause leaks or even structural problems, a problem made worse if you get beach sand inside the mast hole. I have seen some Sunfish that have been sailed without a plastic base cap on the bottom of the mast, and the raw metal edge of the mast acts like a cookie cutter as it rotates from tack to tack over time. That said, if you use a mast cleat for the halyard, be sure to run the slack end of the line through the deck eye and cleat it off loosely to avoid having the entire rig fall out of the mast hole in a capsize.

For the last few years, I have used a small, open ended clam cleat rather than a horn cleat and this rig works fine even when I use the slack end of the halyard to make a boom vang.

Alan Glos

Cazenovia NY

For the last few years, I have used a small, open ended clam cleat rather than a horn cleat and this rig works fine even when I use the slack end of the halyard to make a boom vang.

Alan Glos

Cazenovia NY

Dickhogg

Active Member

Any "insult" to the mast can be expected to cause trouble.

My mast broke in a very strong wind; however, I couldn't find any significant corrosion at the break site. (No different there, than the rest of the mast). I suspect that an overloaded mast can break at roughly the same location on any Sunfish. If an "insult" (corrosion- or drilled-hole) is added, expect that hole to be the site of a break. Higher cleats would be safer for the mast.

Later Sunfish were equipped with an internal sleeve, which can be retrofitted.

View attachment 30436

(This mast had no cleat).

.

This is about where my mast snapped last year. I had no cleat installed or drilled holes.

sadkins372

Member

Did this failure happen where the gooseneck was typically located? It the galvanic reaction of the dissimilar metals caused corrosion this could explain why this was the weak point. ThxAny "insult" to the mast can be expected to cause trouble.

My mast broke in a very strong wind; however, I couldn't find any significant corrosion at the break site. (No different there, than the rest of the mast). I suspect that an overloaded mast can break at roughly the same location on any Sunfish. If an "insult" (corrosion- or drilled-hole) is added, expect that hole to be the site of a break. Higher cleats would be safer for the mast.

Later Sunfish were equipped with an internal sleeve, which can be retrofitted.

View attachment 30436

(This mast had no cleat).

.

Charles Howard

Well-Known Member

Had the same with a fresh water mast at deck level. Got a older replacement and just turned it over.

L&VW

Well-Known Member

The fracture occurred as pictured below; however, I use the "Geezer Rig", which is somewhat higher on the mast.Did this failure happen where the gooseneck was typically located? It the galvanic reaction of the dissimilar metals caused corrosion this could explain why this was the weak point. Thx

As a used Sunfish, I can't account as to what height prior owners hoisted their sails. The broken mast was repaired using an interior sleeve and will be sailing with the repaired mast again in about six weeks.