wjejr

Active Member

Hi everyone,

I made a wind indicator for my Sunfish a while ago and have been very happy with it. I thought I would share it here with the hope that someone finds it useful.

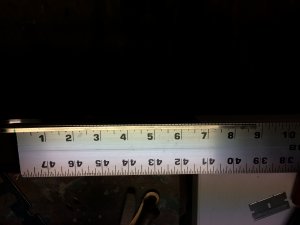

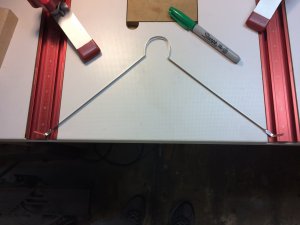

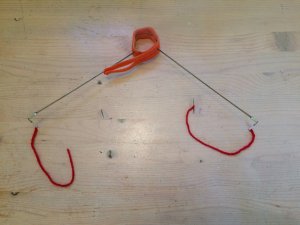

The design is similar in concept to the "coat hangar" model, but uses a flat piece of stainless steel which I think makes it more stable on the upper boom and also more durable. That piece of stainless is readily available for free, but I will let the readers guess its origin and reveal the answer in a couple of days.

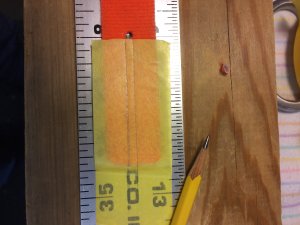

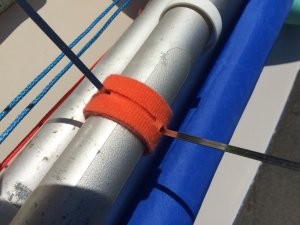

You will notice in the design that the end of the arms turn down which mostly prevents the wool from getting hung up on the arm. Something it likes to do. The wind indicator is held to the boom by two sided velcro, so it can be easily attached and removed at the end.

I started writing descriptions for each picture, but I stopped as I think you can figure it out just by looking. There are more than 30 photos, so I will make a few posts.

If there are any questions please let me know.

I made a wind indicator for my Sunfish a while ago and have been very happy with it. I thought I would share it here with the hope that someone finds it useful.

The design is similar in concept to the "coat hangar" model, but uses a flat piece of stainless steel which I think makes it more stable on the upper boom and also more durable. That piece of stainless is readily available for free, but I will let the readers guess its origin and reveal the answer in a couple of days.

You will notice in the design that the end of the arms turn down which mostly prevents the wool from getting hung up on the arm. Something it likes to do. The wind indicator is held to the boom by two sided velcro, so it can be easily attached and removed at the end.

I started writing descriptions for each picture, but I stopped as I think you can figure it out just by looking. There are more than 30 photos, so I will make a few posts.

If there are any questions please let me know.