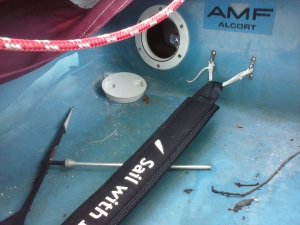

Alright, so I have a sunfish with a large crack in the fiberglass right along the chine where the starboard side of the hull meets the bottom of the hull, pretty much right next to the cockpit. Pictures attached.

Once I sanded down the crack to clear out the damaged fiberglass, I discovered that there's a foam strip running the length of the joint (presumably for reinforcement) which is also cracked. The hull surrounding the crack is solid, but there's a good amount of flex in the bottom directly under the crack (because there's nothing keeping it rigid to the side of the hull).

What's the best way to repair this?

My initial thought was to put an inspection port either on the deck next to the daggerboard slot or on the front wall of the cockpit, but I'm not sure if I should either glass over the broken foam strip (is this recommended?) or remove it and just glass over the corner joint on the inside and outside. I'm also not sure if I'll even be able to access this portion of the boat given the diagrams of where the larger foam blocks inside the hull are located.

Thoughts.....?

Once I sanded down the crack to clear out the damaged fiberglass, I discovered that there's a foam strip running the length of the joint (presumably for reinforcement) which is also cracked. The hull surrounding the crack is solid, but there's a good amount of flex in the bottom directly under the crack (because there's nothing keeping it rigid to the side of the hull).

What's the best way to repair this?

My initial thought was to put an inspection port either on the deck next to the daggerboard slot or on the front wall of the cockpit, but I'm not sure if I should either glass over the broken foam strip (is this recommended?) or remove it and just glass over the corner joint on the inside and outside. I'm also not sure if I'll even be able to access this portion of the boat given the diagrams of where the larger foam blocks inside the hull are located.

Thoughts.....?