andyatos

Well-Known Member

Yes, I know... that seems like a silly question to most of you. But my brother and brother in law can't figure out how to do it. The story goes like this.

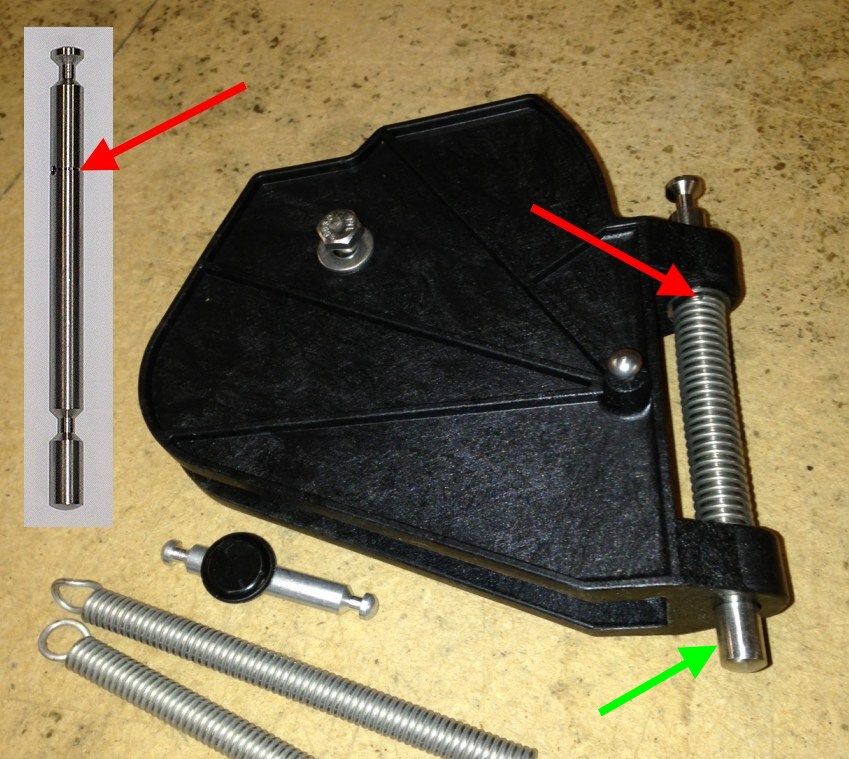

After putting a ton of work into upgrading both Sunfishes, I get a text from my brother... complaining that someone (likely my sister) bent the bottom of the pintle on the brand new rudder head. Anyway, I sent him this photo. The green arrow is where the pintle is bent.

I tell him that it's likely that there's a ring where the red arrows are pointing to that when removed will allow the pintle to be pulled out the bottom of the rudder head. But even after next day shipping another new pintle from Intensity (the photo on the left), my brother and brother in law were not able to figure out how to replace the pintle. I know, I know... but there's more.

Now my brother's plan is to have a boat company... that charges close to $100 per hour... "fix" the rudder. I know... you can't make this stuff up.

So, how hard can it be? Please help my poor (helpless) brother.

Thanks fellow Sunfish-ers,

- Andy

After putting a ton of work into upgrading both Sunfishes, I get a text from my brother... complaining that someone (likely my sister) bent the bottom of the pintle on the brand new rudder head. Anyway, I sent him this photo. The green arrow is where the pintle is bent.

I tell him that it's likely that there's a ring where the red arrows are pointing to that when removed will allow the pintle to be pulled out the bottom of the rudder head. But even after next day shipping another new pintle from Intensity (the photo on the left), my brother and brother in law were not able to figure out how to replace the pintle. I know, I know... but there's more.

Now my brother's plan is to have a boat company... that charges close to $100 per hour... "fix" the rudder. I know... you can't make this stuff up.

So, how hard can it be? Please help my poor (helpless) brother.

Thanks fellow Sunfish-ers,

- Andy