Oliver Kane-Smith

New Member

Hello everyone

I was wondering if I could get some advice on how to fix an issue with my boat.

I have a laser that i believe is from the mid 70s. (I am unsure as my grandfather bought it second hand in the 80s long before I was born but it is dark green).

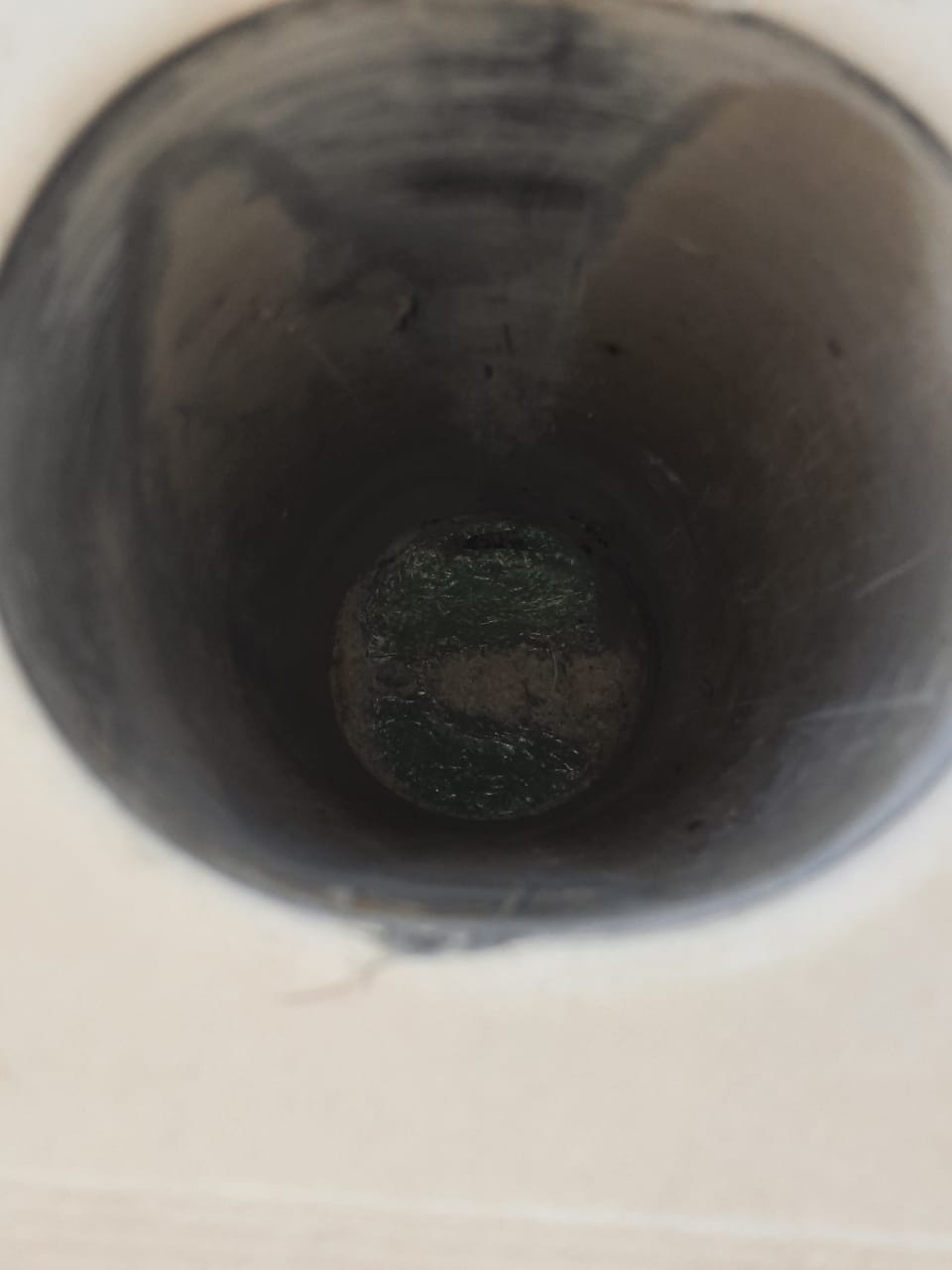

Unfortunately it has developed a small hole at the bottom of the mast step collum from the mast being inserted various time over the years.

My immediate idea for a fix would be to use a small amount of fiber glass and some resin to patch the hole and protect the hull under the mast.

I would love to know if this is a good idea.

Thanks for the help

I was wondering if I could get some advice on how to fix an issue with my boat.

I have a laser that i believe is from the mid 70s. (I am unsure as my grandfather bought it second hand in the 80s long before I was born but it is dark green).

Unfortunately it has developed a small hole at the bottom of the mast step collum from the mast being inserted various time over the years.

My immediate idea for a fix would be to use a small amount of fiber glass and some resin to patch the hole and protect the hull under the mast.

I would love to know if this is a good idea.

Thanks for the help

Yes, of course you need to patch it, a quick fix from the outside should be easy. In the long run, though, you want to restore the inside of the mast step to the original level, and protect it with an anti-abrasion disc. Does the step leak water into the inside of the hull?

Yes, of course you need to patch it, a quick fix from the outside should be easy. In the long run, though, you want to restore the inside of the mast step to the original level, and protect it with an anti-abrasion disc. Does the step leak water into the inside of the hull?