CHIP flipped. Deck fairing next.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1963 Alcort Wooden Sunfish CHIP Restoration

- Thread starter signal charlie

- Start date

-

- Tags

- wooden sunfish

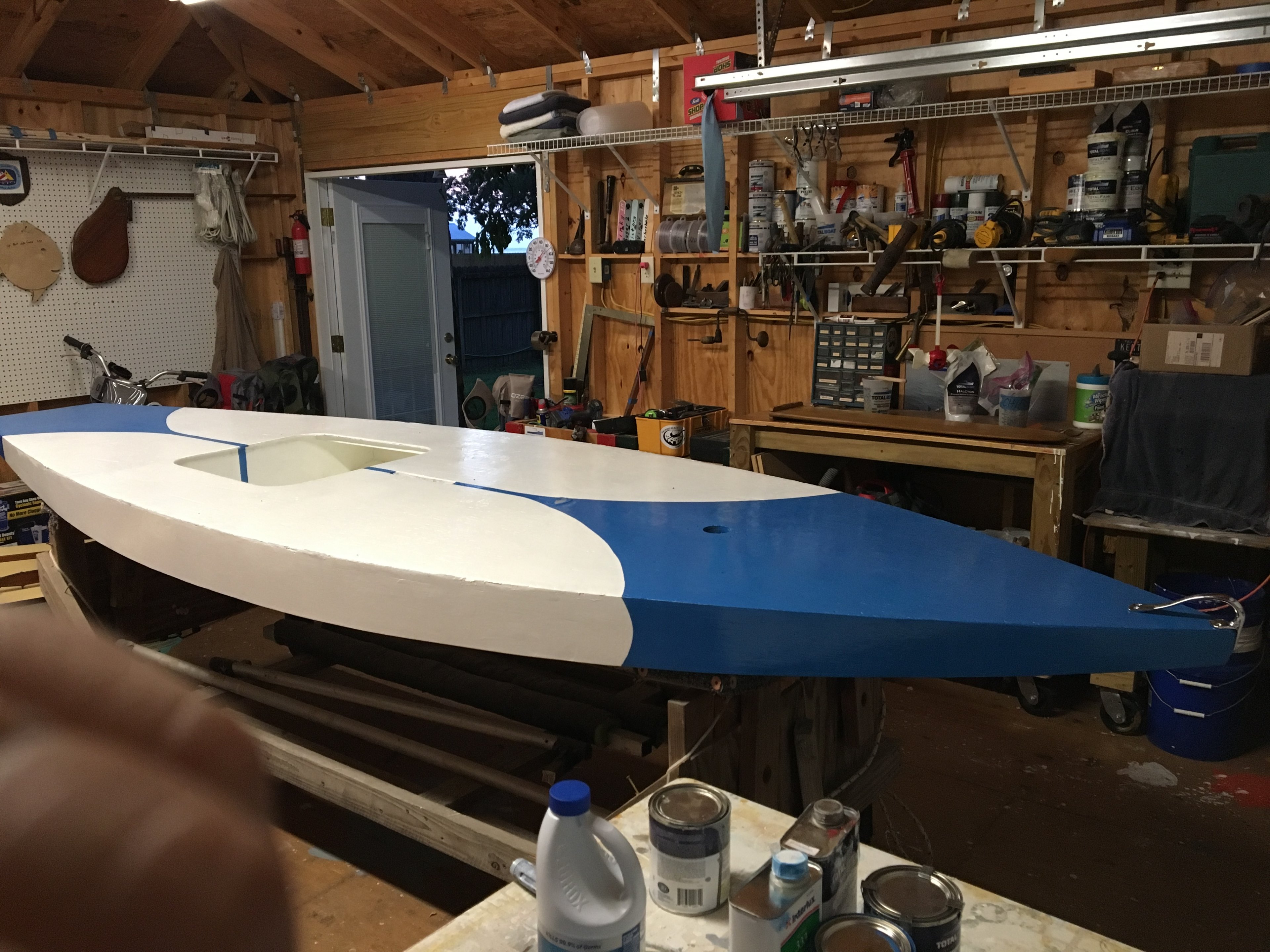

Primed with TotalBoat Topside Primer, mixed gray and white together because that's what I had. Sanded lightly with 120. Laid out the stripes and swoosh.

TotalBoat Halcyon for the daggerboard. Love the Pour Pack! And no sanding between coats. Clean up with soap and water. I only put on a couple of coats so I don't know how it looks if you are one of the 6-8 coat people.

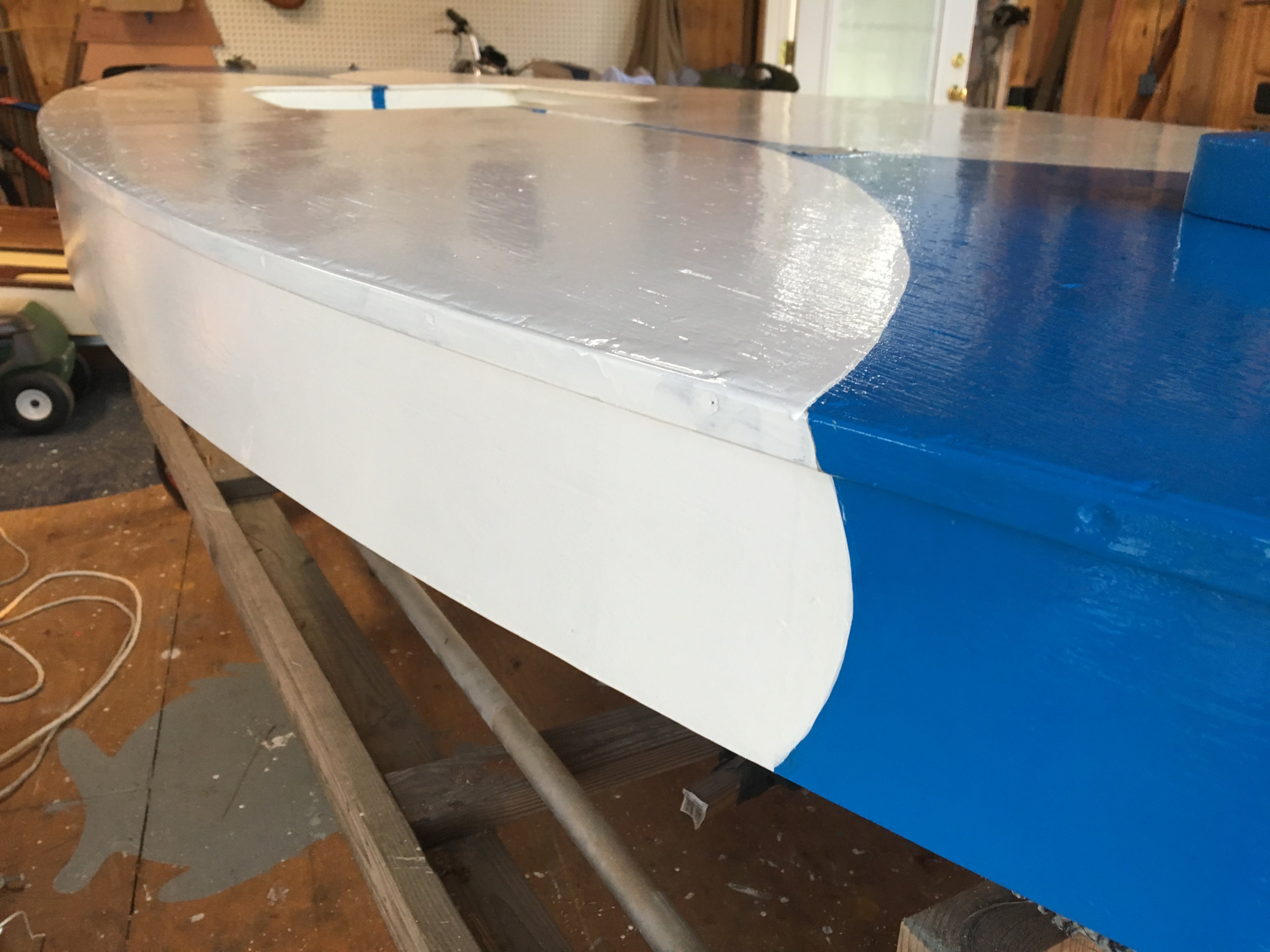

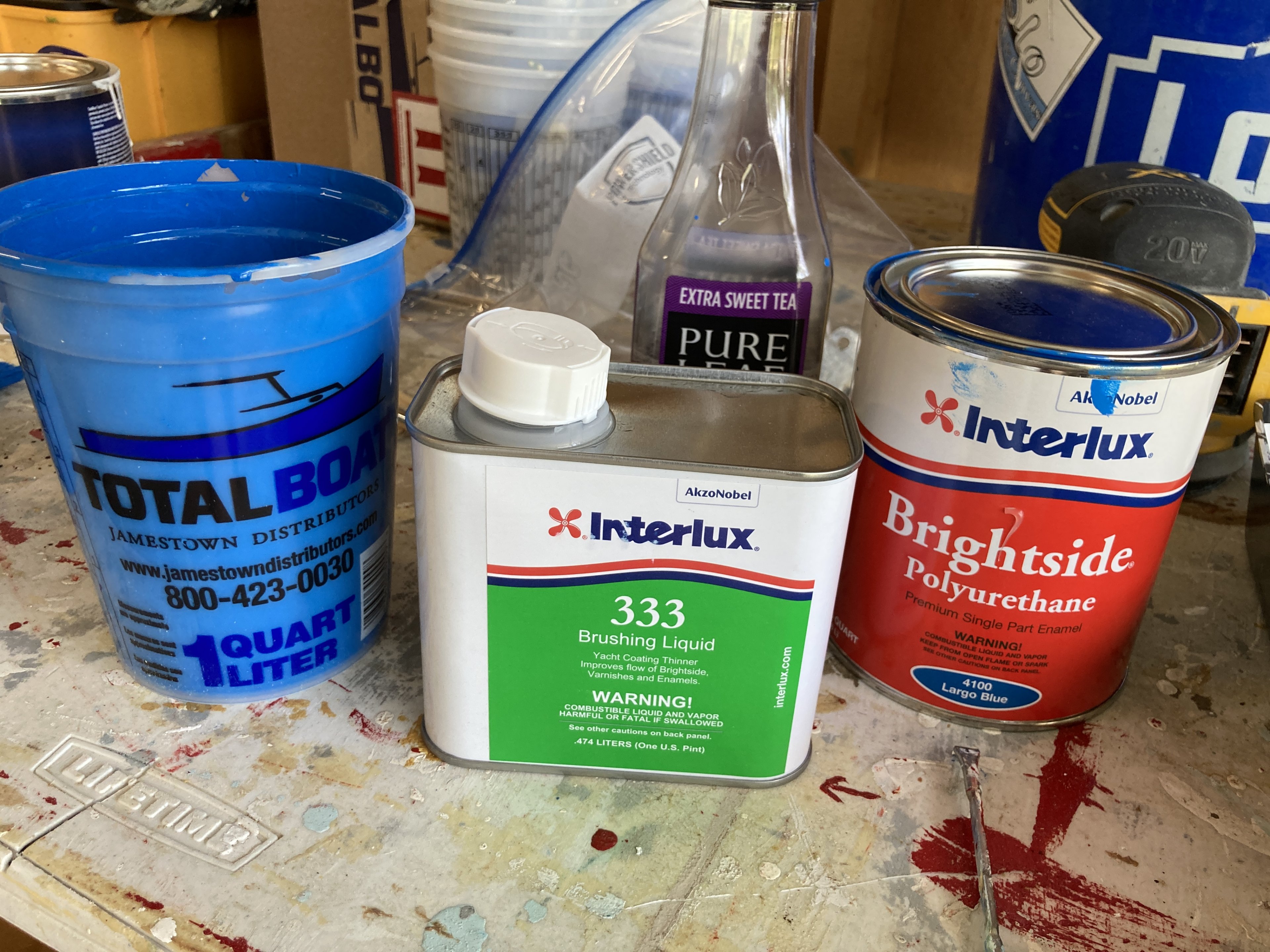

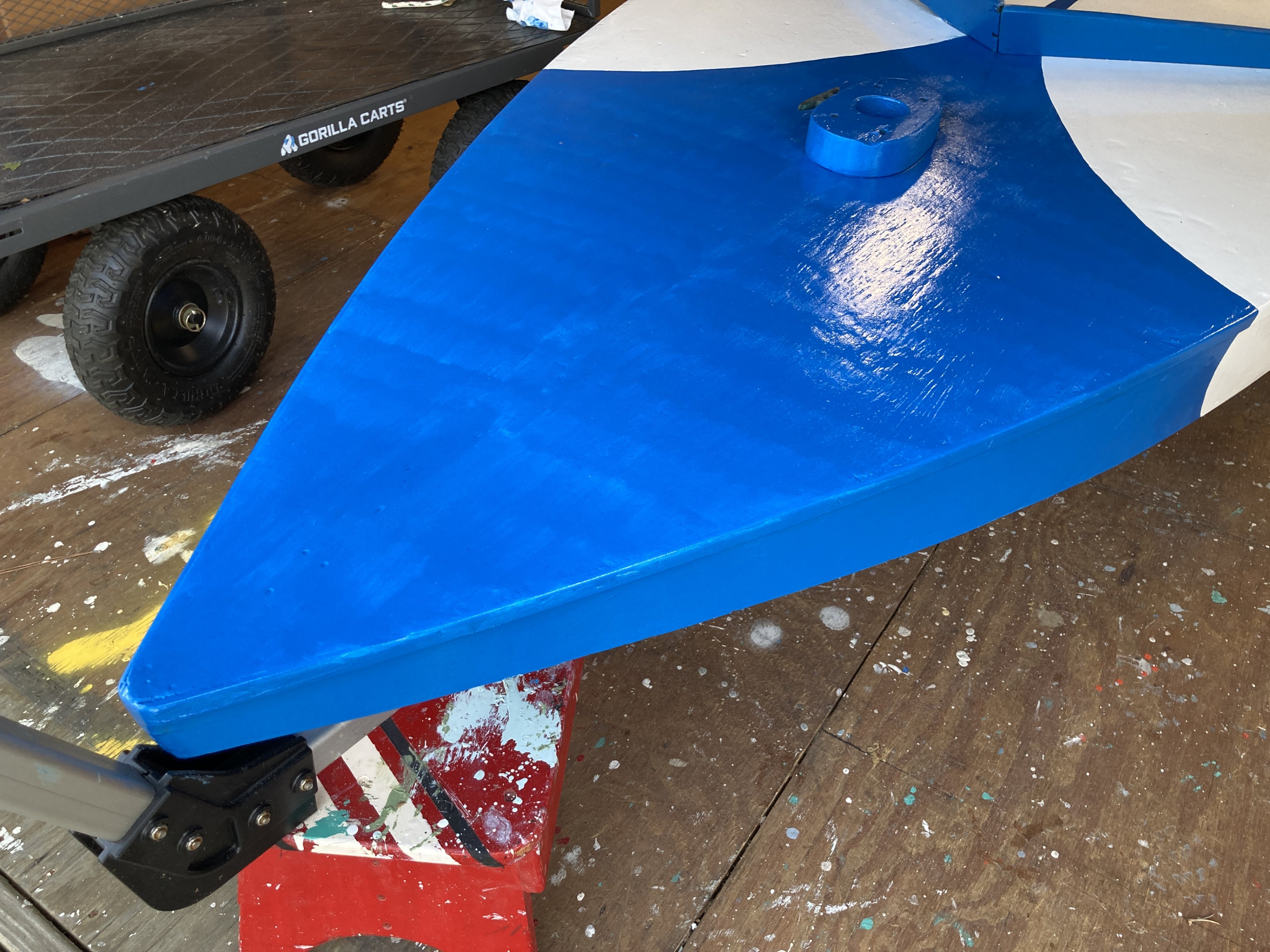

Two coats of Interlux Brightside Largo Blue and TotalBoat WetEdge BluGlo White. I laid down one thinned coat with a brush then hot coated the second coat, filling grain along the way. I had planned to put a skim coat of fairing over the entire deck but ended up just filling screw and nail holes instead, and a few deep gouges, that way we can still enjoy the wood grain pattern up close.

TotalBoat Halcyon for the daggerboard. Love the Pour Pack! And no sanding between coats. Clean up with soap and water. I only put on a couple of coats so I don't know how it looks if you are one of the 6-8 coat people.

Two coats of Interlux Brightside Largo Blue and TotalBoat WetEdge BluGlo White. I laid down one thinned coat with a brush then hot coated the second coat, filling grain along the way. I had planned to put a skim coat of fairing over the entire deck but ended up just filling screw and nail holes instead, and a few deep gouges, that way we can still enjoy the wood grain pattern up close.

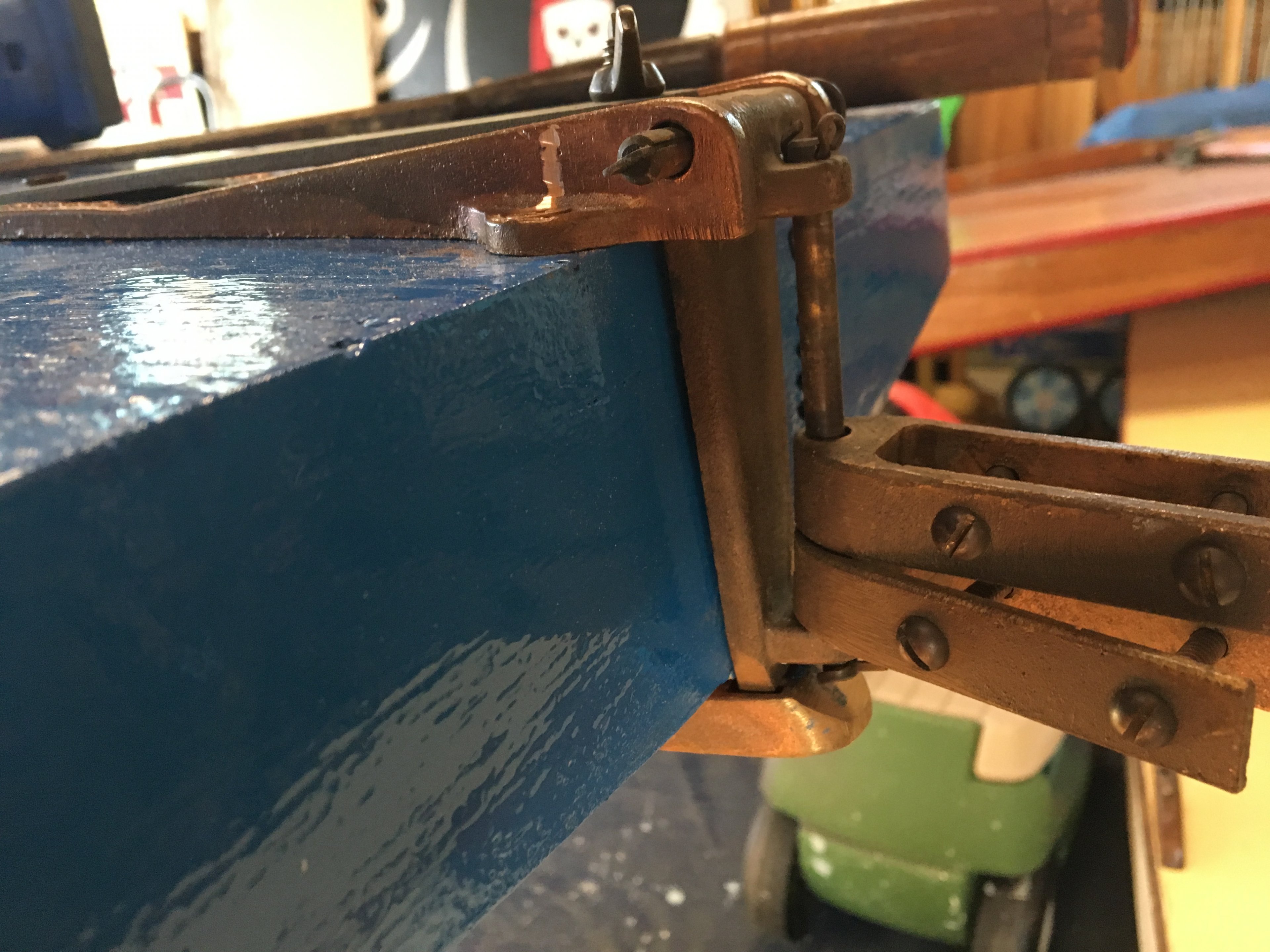

Fit the rudder assembly to the hull, had to trim the last inch or so of the keel strip so that the latch plate fits over it.

Rudder and tiller with 2 coats of TotalBoat Halcyon Rugged Amber Gloss Varnish. The Pour Pack is very handy, and the soap and water cleanup was nice. We have been getting soft satin finishes with a couple of coats, and have not put on a lot of coats to build layers to see if it gets a deep gloss like Epifanes or Pettit, so not sure how it will perform if you want a deep gloss. Recoat in one hour, no sanding between coats.

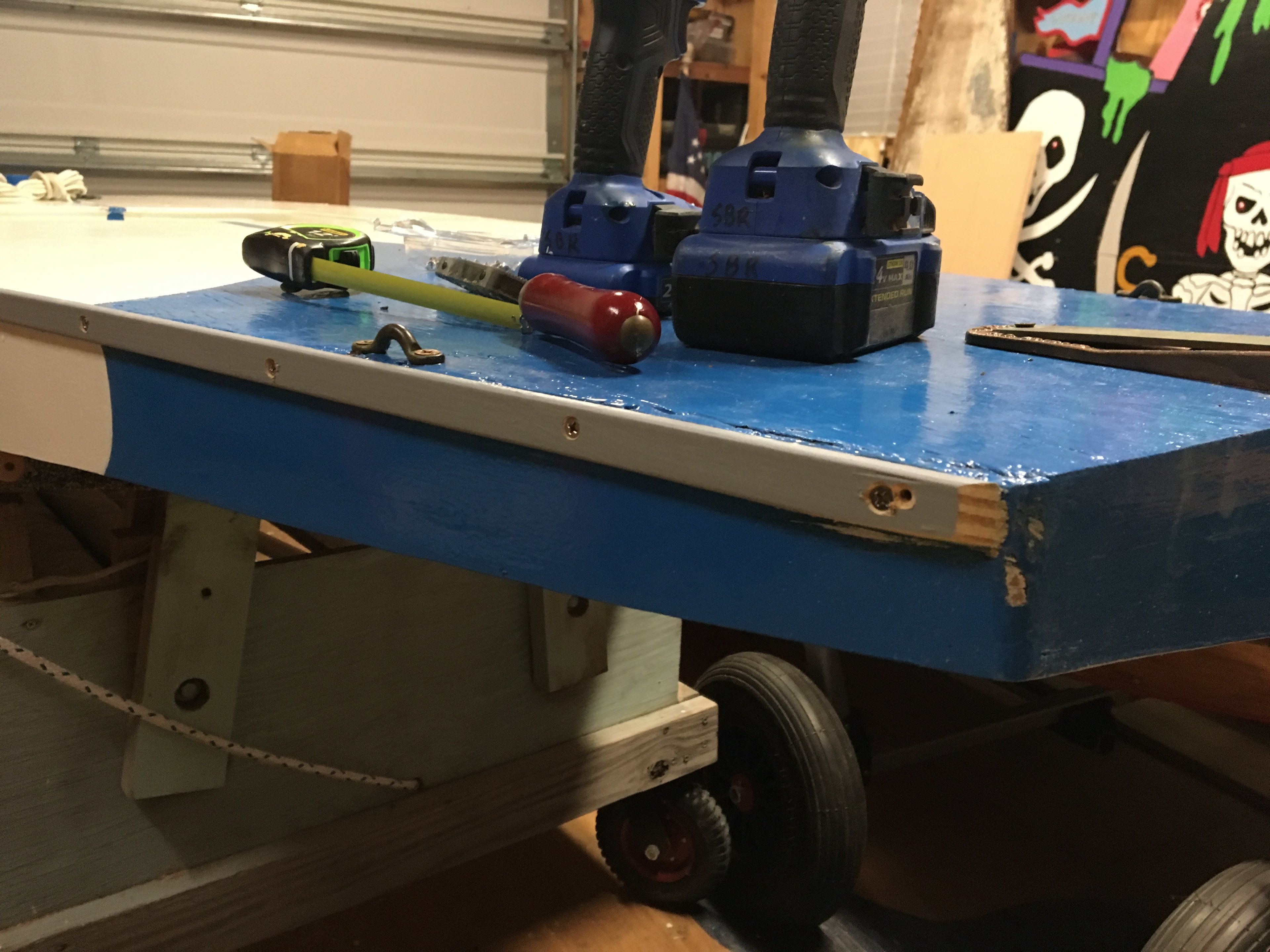

Fitting the rub strip. Screw heads will be puttied over and it will be painted to match.

The "Moaning Chair" is described by Howard Chappelle as an essential tool to have, the place where you sit and ponder what you have either just screwed up or are about to screw up with all of your other tools. Moaning chairs come in all shapes and sizes and can be found next to favorite beverages. Moaning chairs should be available for all of the "usual visitors" as well so they can point out any mistakes the builder might have missed.

We always have 2 projects going, a primary boat and we have what we call a moaning chair "boat", the boat we work on while we contemplate issues with the first boat or just take a break from it for a bit to appreciate it. Our Moaning Chair boat today was SCOUT, our 1960s Grumman 17 double ended canoe. We have toyed with the idea of a sail rig for a while, and pulled together some bits for a 41 sf gaff rig. Old mast that Alan brought us, it is a bit longer than a Sunfish mast so not sure what it goes to. Then we went to Lowes for closet rods for boom and gaff, some 1x8 pine for a mast step, painter's drop cloth and some clear RustOleum to seal up the cloth weave. The Grumman is nice because it already has fittings in the bilge for a gunter rig and sheet block, plus predrilled holes in the gunwale for a thwart, that took the guesswork out of where to put the rig. We went simple with control boards, she will steer with the paddle, like the Seminoles used to do.

Got enough bits together for a test sail to check balance and controllability.

Rudder and tiller with 2 coats of TotalBoat Halcyon Rugged Amber Gloss Varnish. The Pour Pack is very handy, and the soap and water cleanup was nice. We have been getting soft satin finishes with a couple of coats, and have not put on a lot of coats to build layers to see if it gets a deep gloss like Epifanes or Pettit, so not sure how it will perform if you want a deep gloss. Recoat in one hour, no sanding between coats.

Fitting the rub strip. Screw heads will be puttied over and it will be painted to match.

The "Moaning Chair" is described by Howard Chappelle as an essential tool to have, the place where you sit and ponder what you have either just screwed up or are about to screw up with all of your other tools. Moaning chairs come in all shapes and sizes and can be found next to favorite beverages. Moaning chairs should be available for all of the "usual visitors" as well so they can point out any mistakes the builder might have missed.

We always have 2 projects going, a primary boat and we have what we call a moaning chair "boat", the boat we work on while we contemplate issues with the first boat or just take a break from it for a bit to appreciate it. Our Moaning Chair boat today was SCOUT, our 1960s Grumman 17 double ended canoe. We have toyed with the idea of a sail rig for a while, and pulled together some bits for a 41 sf gaff rig. Old mast that Alan brought us, it is a bit longer than a Sunfish mast so not sure what it goes to. Then we went to Lowes for closet rods for boom and gaff, some 1x8 pine for a mast step, painter's drop cloth and some clear RustOleum to seal up the cloth weave. The Grumman is nice because it already has fittings in the bilge for a gunter rig and sheet block, plus predrilled holes in the gunwale for a thwart, that took the guesswork out of where to put the rig. We went simple with control boards, she will steer with the paddle, like the Seminoles used to do.

Got enough bits together for a test sail to check balance and controllability.

Breeze Bender

Breeze Bender

Simply beautiful!

Had an idea...

L&VW

Well-Known Member

Had an idea...

How would it sail now that the center of effort has been moved aft?

For your canoe, you could get away with a single leeboard, but the crossmember should be made of metal. The crossmember should be shaped like an "L", with the bottom about the size of a postcard, and, if aluminum, ⅜" thick. Its two-clamp placement would be about one foot aft of the mast. I'll send a picture of the shape I'd copied from Grumman, but re-made and enlarged in ½" marine plywood.

Those original parts were sold to a chap in Maine, who wanted sail-power for his Folbot kayak—Of which, I have two.

.

Attachments

L&VW

Well-Known Member

How would it sail now that the center of effort has been moved aft? For your canoe, you could get away with a single leeboard, but the crossmember should be made of metal. The crossmember should be shaped like an "L", with the bottom about the size of a postcard, and, if aluminum, ⅜" thick. Its two-clamp placement would be about one foot aft of the mast. I'll send a picture of the shape I'd copied from Grumman, but re-made and enlarged in ½" marine plywood. Those original parts were sold to a chap in Maine, who wanted sail-power for his Folbot kayak—Of which, I have two.

.

As promised—The general shape of the Grumman leeboard for their sailing canoe. Although this leeboard (1 of 2) is almost twice as wide as the original, the shape follows the leading and trailing edges. Put another way: you could remove the center 2-½ inches, vertically, and have the size and shape of the original.

As promised—The general shape of the Grumman leeboard for their sailing canoe. Although this leeboard (1 of 2) is almost twice as wide as the original, the shape follows the leading and trailing edges. Put another way: you could remove the center 2-½ inches, vertically, and have the size and shape of the original. Great! WHat's the length, I was thinking a Shadow or Barrington board may work, although we are going to try adding a mizzen first...to the canoe.

Back to CHIP, we sanded the rubrail with 120 grit on a DeWALT random orbital sander and applied the first coat of paint.

Back to CHIP, we sanded the rubrail with 120 grit on a DeWALT random orbital sander and applied the first coat of paint.

Breeze Bender

Breeze Bender

Love it! That’s a head-turner!

Sail is laced onto the spars with 1/8th inch diameter line from New England Ropes.

Installed the coaming and some other bits. Made the floorboards and applied first coat of paint.

She seems to be ready for Sea Trials...

Installed the coaming and some other bits. Made the floorboards and applied first coat of paint.

She seems to be ready for Sea Trials...

CHIP moved off the finishing dolly and onto WAVE's Dynamic Dolly, preparation for Sea Trials.

Current state of the Sunfish Shack, (L-R): Penobscot 14 ST. JACQUES, 1955 Alcort Super Sailfish ZSA ZSA, 1981 AMF Alcort Sunfish MADISON, 1982 AMF ALcort Sunfish PHOENIX and 1963 wooden Alcort Sunfish CHIP.

Current state of the Sunfish Shack, (L-R): Penobscot 14 ST. JACQUES, 1955 Alcort Super Sailfish ZSA ZSA, 1981 AMF Alcort Sunfish MADISON, 1982 AMF ALcort Sunfish PHOENIX and 1963 wooden Alcort Sunfish CHIP.

Sea Trials! CHIP did awesome, 14-17 mph winds and a lot of chop on the bay. We shipped a lot of water into the cockpit. The rig held up great, she felt very stable and the sail set beautifully.

L&VW

Well-Known Member

It's 31-inches from bottom to the point of attachment. (The original had a 4-inch handle which made it unnecessarily longerGreat! WHat's the length, I was thinking a Shadow or Barrington board may work, although we are going to try adding a mizzen first...to the canoe.

so I left it off).

so I left it off). Back to CHIP...

.

Thanks L&VW! Nice to have measurements to get in the ball park, then get creative with handles, control lines, edge shapes, lengths etc...

Functional Check Float (FCF) and Sea Trial report for CHIP 17 Jul 19:

So the Skipper and I wandered out to the dock to see if it really was 98F heat index and it was, but while we were out there we noticed that the breeze was blowing steady around 12-14 knots, perpendicular to the shoreline, perfect for a long reach out and a long reach back. We both had the same thought at the same time. I asked her if I took CHIP out would she take pictures. She said no, but she'd take her out and I could get pictures. We knew we would not be out long with the heat and So she went to get the PFDs and the camera and I went to the garage to get the sail. Took the sail down to the beach and then rolled CHIP from the Sunfish Shack over to Sunfish Beach. We had already test rigged CHIP the day before so the setup went quick. I stepped the mast and left the sail down.

Next I pinned on the rudder. We leave the wing nut loose on the carriage bolt, slide the bottom of the vertical plate into the latch plate, pin the top of the vertical plate then tighten down the wing nut. We leave a little play so that the rudder can release if it hits something hard, but not too loose as to pop out under sail. While I was back at the stern I attached the sheet snap shackle to the bridle.

Next step was to get CHIP in the water, so I rolled the dolly down the beach, got CHIP into the bay and Skipper pulled the dolly back up onto the beach. Took a peak in the cockpit bilge, no water, good. Spun CHIP around, raised the sail and tied off the halyard to the halyard cleat. On the wooden boats there is no block, just a cleat screwed to the side of a wooden mast collar. The Old School way to secure the tail of the halyard is to wrap it around the base of the mast and halyard, that takes about 25 wraps and I didn't want to take time to do that while the boat was bucking in rolling waves, plus it is impossible to get the sail down quickly if needed. Got the sail up and let it luff.

Skipper climbed aboard and she put in the daggerboard. We keep it simple with just a retaining line so she can adjust it easily and pull it out when beaching, for us a bungee adds complication. She took off on a beam reach and was out past the end of the 250 foot dock in no time. She did a couple of tacks to make sure the rudder and rigging were working right and then headed out to the Deep Blue.

The early wooden Sunfish does not even have a sheet hook, so in the spirit of Vintage we didn't add one. If you are thinking about getting a gym membership, I'd recommend getting a wooden Sunfish. Sail it for a few months then buy a Sailfish, aka the "Total Gym." The vintage sheet was a little slick, plus 75 square feet of sail was working to pull that line out of Skipper's hand. She wore her sailing gloves, but she said she should have got the leather palms wet first so they gripped a little better. She did lose the sheet once but since there was no hook-swivel-cam-ratchet-spring-block-HarkenStan-cleat to capture the sheet, the sail just luffed into the wind. She took the tiller and steered the bow back into the wind, and when the boom came back over the boat she grabbed the sheet and was off like a shot again.

The bow submarined beautifully and the V shaped coaming got a workout. It was surprisingly effective, has a nice forward angle to the top edge and shed all but the biggest of bow waves. The wooden Fish hulls are not as deep as the fiberglass Sunfish, maybe 3 inches or so more shallow, so they don't skim as many wave crests. The bow is a little sharper though, and not as tall, so CHIP kind of pierces the wave vs punching it. And I tell you what, there is no oil canning with these wooden hulls, and no wet foam. Now check out the tiny tiller extension in the photo below. Not only is it small diameter, it is tapered from the tiller bolt down to the tip. And varnished! That was a little bit of an issue. It needs some gaff tape to give it some grip - Done!

Did we mention the vintage 5 panel sail set beautifully? Skipper knows how to maneuver a boat for a photo shoot, puts the rail down for a little theatrical effect.

One of my favorite shots, enjoying the wave form under the hull, perfect conditions to catch a stern wave. We can almost see the daggerboard. The sail looks great with the foot and luff set close to the spars, I'm convinced that line lacing is better aerodynamically than the sail rings, the spars act as end plates to send the airflow aft to the trailing edge of the sail. If the airflow escapes mid spar then it creates turbulent flow. Alan can chime in, I believe he ties his sails, each grommet individually. Our marlin hitch is the lazy way The sheet hangers worked well, but that was probably because we had taut sheets with that wind

The sheet hangers worked well, but that was probably because we had taut sheets with that wind

As soon as I went out I thought I'd see if I could fill the cockpit up with water. Note how I'm holding the tiller extension down by the stubby end. I also found out quick that the floorboards were slick, and my foot slid up off the floorboard and into the cockpit recess, not a good spot. There is a lot more space under the cockpit lip side to side, I think it would be good to block that are off with a towel or, pool noodles or a wooden box as it is an ankle twister. Maybe make little storage boxes to go there.

So the Skipper and I wandered out to the dock to see if it really was 98F heat index and it was, but while we were out there we noticed that the breeze was blowing steady around 12-14 knots, perpendicular to the shoreline, perfect for a long reach out and a long reach back. We both had the same thought at the same time. I asked her if I took CHIP out would she take pictures. She said no, but she'd take her out and I could get pictures. We knew we would not be out long with the heat and So she went to get the PFDs and the camera and I went to the garage to get the sail. Took the sail down to the beach and then rolled CHIP from the Sunfish Shack over to Sunfish Beach. We had already test rigged CHIP the day before so the setup went quick. I stepped the mast and left the sail down.

Next I pinned on the rudder. We leave the wing nut loose on the carriage bolt, slide the bottom of the vertical plate into the latch plate, pin the top of the vertical plate then tighten down the wing nut. We leave a little play so that the rudder can release if it hits something hard, but not too loose as to pop out under sail. While I was back at the stern I attached the sheet snap shackle to the bridle.

Next step was to get CHIP in the water, so I rolled the dolly down the beach, got CHIP into the bay and Skipper pulled the dolly back up onto the beach. Took a peak in the cockpit bilge, no water, good. Spun CHIP around, raised the sail and tied off the halyard to the halyard cleat. On the wooden boats there is no block, just a cleat screwed to the side of a wooden mast collar. The Old School way to secure the tail of the halyard is to wrap it around the base of the mast and halyard, that takes about 25 wraps and I didn't want to take time to do that while the boat was bucking in rolling waves, plus it is impossible to get the sail down quickly if needed. Got the sail up and let it luff.

Skipper climbed aboard and she put in the daggerboard. We keep it simple with just a retaining line so she can adjust it easily and pull it out when beaching, for us a bungee adds complication. She took off on a beam reach and was out past the end of the 250 foot dock in no time. She did a couple of tacks to make sure the rudder and rigging were working right and then headed out to the Deep Blue.

The early wooden Sunfish does not even have a sheet hook, so in the spirit of Vintage we didn't add one. If you are thinking about getting a gym membership, I'd recommend getting a wooden Sunfish. Sail it for a few months then buy a Sailfish, aka the "Total Gym." The vintage sheet was a little slick, plus 75 square feet of sail was working to pull that line out of Skipper's hand. She wore her sailing gloves, but she said she should have got the leather palms wet first so they gripped a little better. She did lose the sheet once but since there was no hook-swivel-cam-ratchet-spring-block-HarkenStan-cleat to capture the sheet, the sail just luffed into the wind. She took the tiller and steered the bow back into the wind, and when the boom came back over the boat she grabbed the sheet and was off like a shot again.

The bow submarined beautifully and the V shaped coaming got a workout. It was surprisingly effective, has a nice forward angle to the top edge and shed all but the biggest of bow waves. The wooden Fish hulls are not as deep as the fiberglass Sunfish, maybe 3 inches or so more shallow, so they don't skim as many wave crests. The bow is a little sharper though, and not as tall, so CHIP kind of pierces the wave vs punching it. And I tell you what, there is no oil canning with these wooden hulls, and no wet foam. Now check out the tiny tiller extension in the photo below. Not only is it small diameter, it is tapered from the tiller bolt down to the tip. And varnished! That was a little bit of an issue. It needs some gaff tape to give it some grip - Done!

Did we mention the vintage 5 panel sail set beautifully? Skipper knows how to maneuver a boat for a photo shoot, puts the rail down for a little theatrical effect.

One of my favorite shots, enjoying the wave form under the hull, perfect conditions to catch a stern wave. We can almost see the daggerboard. The sail looks great with the foot and luff set close to the spars, I'm convinced that line lacing is better aerodynamically than the sail rings, the spars act as end plates to send the airflow aft to the trailing edge of the sail. If the airflow escapes mid spar then it creates turbulent flow. Alan can chime in, I believe he ties his sails, each grommet individually. Our marlin hitch is the lazy way

The sheet hangers worked well, but that was probably because we had taut sheets with that wind

The sheet hangers worked well, but that was probably because we had taut sheets with that windAs soon as I went out I thought I'd see if I could fill the cockpit up with water. Note how I'm holding the tiller extension down by the stubby end. I also found out quick that the floorboards were slick, and my foot slid up off the floorboard and into the cockpit recess, not a good spot. There is a lot more space under the cockpit lip side to side, I think it would be good to block that are off with a towel or, pool noodles or a wooden box as it is an ankle twister. Maybe make little storage boxes to go there.

No Wake Zone. Not for CHIP!

I think we'll start calling this the Daggerboard Shot. I'm getting there, but not as close as Skipper. And capsize doesn't count.

We got CHIP back to the beach, on the dolly, up into the yard and down rigged. Took the sail off and rinsed off the blades. I opened the drain plugs, we got about a 1/4 cup out of the bow compartment and maybe cup out of the aft compartment. My guess is that I did not get the cockpit bulkhead completely sealed, we can do an air leak test to find out. CHIP got rinsed off and went proudly back to the Sunfish Shack, with tall tales to tell.

I think we'll start calling this the Daggerboard Shot. I'm getting there, but not as close as Skipper. And capsize doesn't count.

We got CHIP back to the beach, on the dolly, up into the yard and down rigged. Took the sail off and rinsed off the blades. I opened the drain plugs, we got about a 1/4 cup out of the bow compartment and maybe cup out of the aft compartment. My guess is that I did not get the cockpit bulkhead completely sealed, we can do an air leak test to find out. CHIP got rinsed off and went proudly back to the Sunfish Shack, with tall tales to tell.

andyatos

Well-Known Member

Sea Trials! CHIP did awesome, 14-17 mph winds and a lot of chop on the bay. We shipped a lot of water into the cockpit. The rig held up great, she felt very stable and the sail set beautifully.

Loved the video!

- Andy

mixmkr

Well-Known Member

Great read and pics!

Next adventure for CHIP, air freight shipping to Pt Townsend, WA. How big of a box does it take? Interior dimensions 14 feet, by 4 feet wide by 18 inches high. We had some pros build a box for us and picked it up today with our 5x10 utility trailer. Next step is to pack CHIP and then get the package to Atlanta, where Delta Air Lines will take charge.

Post Hurricane Check Up for CHIP, before we ship. She got banged around a bit during Hurricane Sally, and sitting for 9 months after restoration we found a few small leaks during the Air Leak test that need some thickened epoxy attention.

Poor CHIP still had storm surge debris packed into her trunk. We thought we got it all but missed a chunk.

The mast step is made from stacked layers of oak hardwood, so it would swell and seal with a little moisture, but we will put a coating of thickened epoxy in there as a protective barrier.

Air could be coming through the seam or through the fastener hole. Our plan is to run a thin bead of thickened epoxy all along the bottom of the rub strip to act as a sealant and divert water away from the seam.

Lots of little seams up front, both planks, deck and hull, attached to solid stem and longerons behind the plywood. 2 more coats of paint won't hurt either.

She could go out As Is, but we want to get her really right for her next Skipper.

We used the shop vac for air, but didn't plug it in tight, but rather held the nozzle an inch or so away from the drain plug holes.

Poor CHIP still had storm surge debris packed into her trunk. We thought we got it all but missed a chunk.

The mast step is made from stacked layers of oak hardwood, so it would swell and seal with a little moisture, but we will put a coating of thickened epoxy in there as a protective barrier.

Air could be coming through the seam or through the fastener hole. Our plan is to run a thin bead of thickened epoxy all along the bottom of the rub strip to act as a sealant and divert water away from the seam.

Lots of little seams up front, both planks, deck and hull, attached to solid stem and longerons behind the plywood. 2 more coats of paint won't hurt either.

She could go out As Is, but we want to get her really right for her next Skipper.

We used the shop vac for air, but didn't plug it in tight, but rather held the nozzle an inch or so away from the drain plug holes.

Scuffed the paint with 80 grit. The darker spots are low spots where the 60 year old fir plywood has checked. Fir is notorious for checking, we sanded this original deck enough to get rid of loose bits and snaggy stuff. Primed and painted. Some folks might want to seal with neat epoxy then fair before prime and paint, but we didn't mind the texture. Turns out there were actually a few tiny air leaks through the ply! Who knew?

We actually had a few tiny air leaks through the deck plywood, a combination of the top veneer layer checking and tiny grainwise fractures in the plies underneath. It didn't leak under sail, but to be conservative we are going to try to fill the voids left over from plywood checking with a skim of THIXO.

Filled quite a few shallow depressions on the starboard side deck. Leftover sanding dust colored the THIXO.

An 18:1 High Thrust caulk gun is the way to go when dispensing THIXO or Flexpoxy, we use a Newborn 350 purchased from Jamestown Distributors.

Applied another coat of THIXO to the seam between the deck and inner mast step block, and did the same to the upper and lower daggerboard trunk. There is solid wood in there, and the seam would swell if it got wet, but we are hoping to keep water away from those seams.

We'll let the THIXO skim coat dry, sand it and throw on primer, then paint. Not worried about fairing the deck to be super smooth, the checked areas make good non slip texture

For those of you subscribed to Small Craft Advisor, check out Emiliano Marino's article, there is a surprise in there this issue

We actually had a few tiny air leaks through the deck plywood, a combination of the top veneer layer checking and tiny grainwise fractures in the plies underneath. It didn't leak under sail, but to be conservative we are going to try to fill the voids left over from plywood checking with a skim of THIXO.

Filled quite a few shallow depressions on the starboard side deck. Leftover sanding dust colored the THIXO.

An 18:1 High Thrust caulk gun is the way to go when dispensing THIXO or Flexpoxy, we use a Newborn 350 purchased from Jamestown Distributors.

Applied another coat of THIXO to the seam between the deck and inner mast step block, and did the same to the upper and lower daggerboard trunk. There is solid wood in there, and the seam would swell if it got wet, but we are hoping to keep water away from those seams.

We'll let the THIXO skim coat dry, sand it and throw on primer, then paint. Not worried about fairing the deck to be super smooth, the checked areas make good non slip texture

For those of you subscribed to Small Craft Advisor, check out Emiliano Marino's article, there is a surprise in there this issue

Last edited:

Sanded with 120 then rolled a coat ot TotalBoat Topside Primer.

Painted with TotalBoat WetEdge BluGlo White, rolled and tipped.

First coat of Interlux Brightside Largo Blue, brushed.

Second coat of Largo Blue.

Painted with TotalBoat WetEdge BluGlo White, rolled and tipped.

First coat of Interlux Brightside Largo Blue, brushed.

Second coat of Largo Blue.

CHIP's paint is dry so we reattached the keel strip and bow handle.

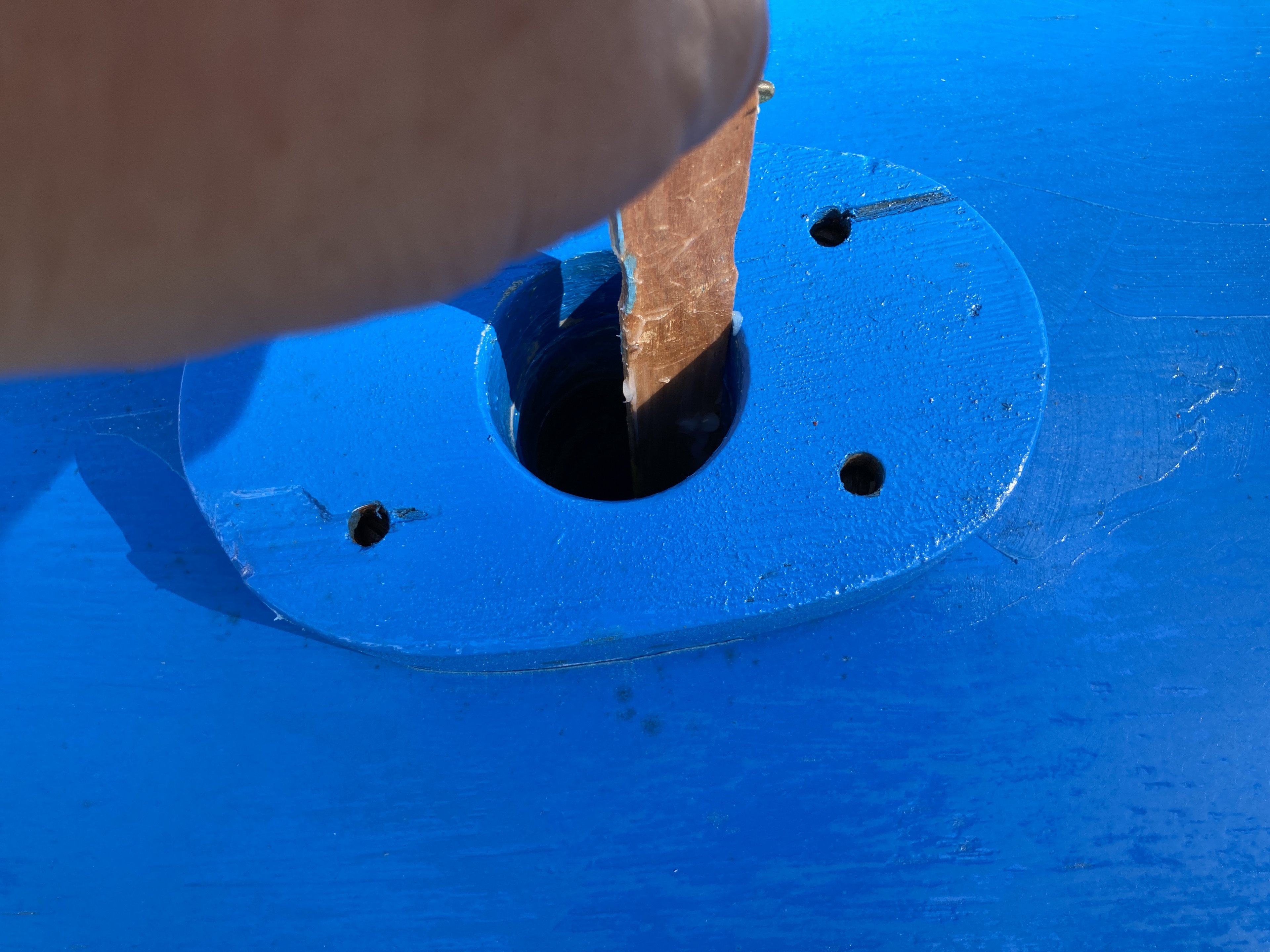

Used the awl to make a starter hole for the wood drill bit.

Drilled a small pilot hole for the marine stainless countersunk oval head screws. The hole was too small, so we snuck up on it one drill bit size at a time.

Began boxing CHIP for the next leg of her odyssey.

Used the awl to make a starter hole for the wood drill bit.

Drilled a small pilot hole for the marine stainless countersunk oval head screws. The hole was too small, so we snuck up on it one drill bit size at a time.

Began boxing CHIP for the next leg of her odyssey.

Shipping saga continues. We added a pallet underneath and had FEDEX set up to pick up the boat, but there were concerns that it might be tempting for a shipper to stack freight on top of the box and it would have been best to add even more pallets on either end.

We cancelled FEDEX and are going to use a PODS container now and let CHIP ride on a dolly. Anyone need a big box?

We cancelled FEDEX and are going to use a PODS container now and let CHIP ride on a dolly. Anyone need a big box?

CHIP made it out for her first voyage in Port Townsend, WA with her new crew, The Artful Sailor's Emiliano Marino. Emiliano is the author of The Sailmaker's Apprentice and along with Salty Sue, they are going to introduce CHIP to the rest of Pt Townsend's Usual Visitors. Huzzah!

![Center-of-Effort-logo[1].jpg](https://cdn.sailingforums.com/attachments/32/32242-a0184bf73b877119f76616aab4277acd.jpg)