lymantuttle

New Member

Hello everyone, newbie here so please be patient with me. I just bought a 1973 sunfish for $200 with everything. Couple of issues of course. She's heavy but I'll be installing some vent ports and trying to dry her out. I did a leak test and she did really well. Found two major leaks. One on the bottom of the hull almost below the cockpit and the other at the bow handle, the screws are loose.

This is my first boat so I don't have a lot of experience with repairs. But hey at $200 it should be a good learning experience all around. My questions are these,

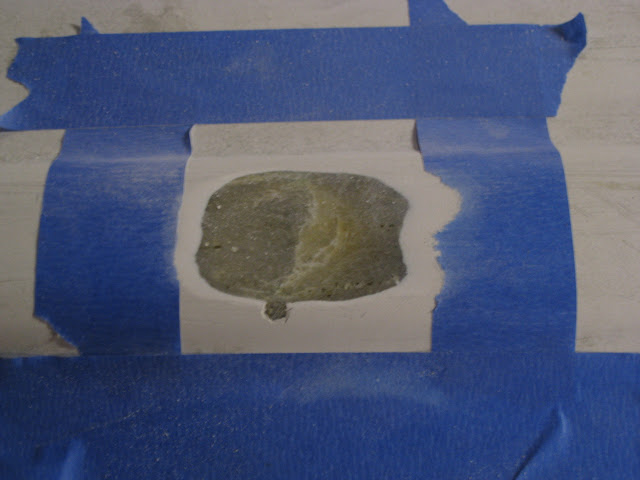

1. How do I tell if there is fiberglass damage underneath the gelcoat? I watched a video by laser and they said to look for "white" fiberglass. Then you sand until you've gotten rid of the white and start over again.

For example do I still have fiberglass damage here?

Should I keep sanding or can I start rebuilding?

2. I also have a few spider cracks that radiate out, but during my leak test they showed no bubbles. I can just widen these out with a dremel and gelcoat right? Should I sand them down and see how far down I go to make them go away?

These are all in the same general area of the bottom of the boat. I think someone must have dropped the boat on this side.

I only had a leak coming from here, but as you can tell I've all ready cut out the offending crack and widened it out to start the repair. I am only going to use a small strip of carboard as I have the foam block to use for most of the hole to secure the fiberglass patch. I just need to bevel it out with the orbit sander so I can do the layers.

Thanks y'all in advance. If by the way you are anywhere near Durham NC and want to swing by and help someone get in the water soon let me know. I'll take all the help I can get. I am thinking of going ahead and putting in an access hole on top while I have the hole on the bottom and drying out the boat. She's pretty heavy and needs some drying out I am sure.

J

This is my first boat so I don't have a lot of experience with repairs. But hey at $200 it should be a good learning experience all around. My questions are these,

1. How do I tell if there is fiberglass damage underneath the gelcoat? I watched a video by laser and they said to look for "white" fiberglass. Then you sand until you've gotten rid of the white and start over again.

For example do I still have fiberglass damage here?

Should I keep sanding or can I start rebuilding?

2. I also have a few spider cracks that radiate out, but during my leak test they showed no bubbles. I can just widen these out with a dremel and gelcoat right? Should I sand them down and see how far down I go to make them go away?

These are all in the same general area of the bottom of the boat. I think someone must have dropped the boat on this side.

I only had a leak coming from here, but as you can tell I've all ready cut out the offending crack and widened it out to start the repair. I am only going to use a small strip of carboard as I have the foam block to use for most of the hole to secure the fiberglass patch. I just need to bevel it out with the orbit sander so I can do the layers.

Thanks y'all in advance. If by the way you are anywhere near Durham NC and want to swing by and help someone get in the water soon let me know. I'll take all the help I can get. I am thinking of going ahead and putting in an access hole on top while I have the hole on the bottom and drying out the boat. She's pretty heavy and needs some drying out I am sure.

J