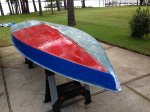

I bought a mast, sails and spars on craigslist from a guy last year, he offered hull gratis but it was in SAD shape. It scared me so I backed away. Fast forward to 2013 and I feel ready to tackle it as a project, so we called and he still had it. Picked it up and brought it home for restoration. It has been over sanded, painted, transom is ugly and hull is really crunchy, lots of gel coat missing and a crack on keel.

Good news is boat has a hole in bow, inspection port in stern and crack in keel, so there is now way water cloud be trapped in the boat and saturate the foam it is a pre 1972 hull and the weight is not too bad at 144.5

it is a pre 1972 hull and the weight is not too bad at 144.5

The boat told my wife "Merci beaucoup" when we hauled her out of the yard, so her name is "Merci."

Good news is boat has a hole in bow, inspection port in stern and crack in keel, so there is now way water cloud be trapped in the boat and saturate the foam

it is a pre 1972 hull and the weight is not too bad at 144.5

it is a pre 1972 hull and the weight is not too bad at 144.5The boat told my wife "Merci beaucoup" when we hauled her out of the yard, so her name is "Merci."