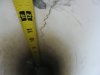

Well, I have gathered the necessary "stuff" to start a repair on the mast step. I wasnt sure if there was anything wrong with the bottom of the tube where it is affixed to the hull; but I knew the inside of the tube needed work. Someone had poured epoxy in the tube and evidently the boat wasnt level. As you can see in the first picture there was a bubble in the bottom of the tube. So i cut a length of pipe ( i had some light duty gauge pipe left over from making gates) to protect the tube and started "sanding". The sandpaper would get hot and the glue would turn loose of the sand paper; so i ended up using some course material which i cut down to fit the tube. this would work well enough. I ended up dropping the "floor" of the tube down to about 14 1/8". I basically removed about 3/4 of an inch of material.

I cut the deck for an inspection port to build up and/or repair the bottom of the mast step. The bottom of the mast step actually looks pretty good. WOW. I will still sand the entire area; build a little fillet of epoxy and coillodal around the bottom of the tube and then apply strips of fiberglass around the tube down to the hull.

I want to thank this forum for all the helpfull threads which provide well photoed documentation so that i am not going into this project "blind". Speakling of blind... Man i am so close to cutting another inspection port on the starboard side to enable working around the entire mast tube. But I can get the job done fine like it is.

Thanks!

Raymond

I cut the deck for an inspection port to build up and/or repair the bottom of the mast step. The bottom of the mast step actually looks pretty good. WOW. I will still sand the entire area; build a little fillet of epoxy and coillodal around the bottom of the tube and then apply strips of fiberglass around the tube down to the hull.

I want to thank this forum for all the helpfull threads which provide well photoed documentation so that i am not going into this project "blind". Speakling of blind... Man i am so close to cutting another inspection port on the starboard side to enable working around the entire mast tube. But I can get the job done fine like it is.

Thanks!

Raymond