John McKee

New Member

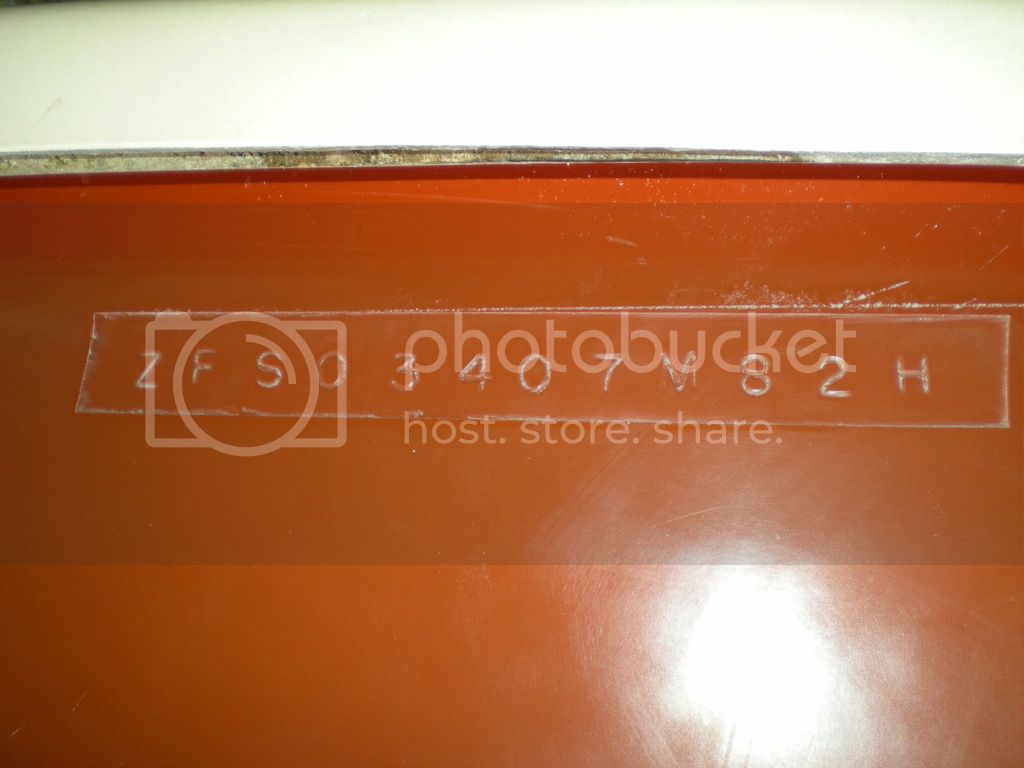

My first post. Thank you for all the helpful advice gleaned from these threads. This Laser 2 had been sitting, topside up, in somebody's North Carolina back yard for years. The remnants of a covering, tattered. The drain of the cockpit clogged as the owner got old and sick. And several winters or more of standing water in the cockpit. A little scary at first to look at. Until you looked around and realized the cockpit floor was bad but fixable. The deck appeared firm and the hull problem free. I started with the hull. And worked several days to remove the dull and discolored finish.

Then worked the old caulk material from the deck/hull joint for several days. The complete joint, cleaned out. I'm waiting for the mail. To use West G-Flex to reseal and bond the deck/hull.

With that done and waiting I went inside the hull to determine what was up with the noise of old wood rattling around. I have several observations and would appreciate your comments. The first was the mast step. It's a two part, 3 piece step. The top of the step looks like balsa wood and is in great shape. The lower piece of wood looks like old oak. 2) 6"x 2"x 1/2" And this 2 piece combo completely shot. I thought I would replace with mahogany or teak. The foot where they fit in is fine. I can bond them back into place.

With that done and waiting I went inside the hull to determine what was up with the noise of old wood rattling around. I have several observations and would appreciate your comments. The first was the mast step. It's a two part, 3 piece step. The top of the step looks like balsa wood and is in great shape. The lower piece of wood looks like old oak. 2) 6"x 2"x 1/2" And this 2 piece combo completely shot. I thought I would replace with mahogany or teak. The foot where they fit in is fine. I can bond them back into place.

(these are taken with the boat upside down)

More curious is the rest of the wood.

This is a picture of the centerboard-forward..... not pretty...but functional?!? Showing the remnants

of a very thin plywood, sprayed with chopped glass into place, stringer? going across the boat just aft of the step and before the cockpit. It's so thin as to be useless structurally? I'm not sure to ignore it and just let it be. The other good news is the bow to mast step, wood "stringer". Which is clean and dry.

I appreciate, very much, any comments you may have.

I appreciate, very much, any comments you may have.

Then worked the old caulk material from the deck/hull joint for several days. The complete joint, cleaned out. I'm waiting for the mail. To use West G-Flex to reseal and bond the deck/hull.

(these are taken with the boat upside down)

More curious is the rest of the wood.

This is a picture of the centerboard-forward..... not pretty...but functional?!? Showing the remnants

of a very thin plywood, sprayed with chopped glass into place, stringer? going across the boat just aft of the step and before the cockpit. It's so thin as to be useless structurally? I'm not sure to ignore it and just let it be. The other good news is the bow to mast step, wood "stringer". Which is clean and dry.

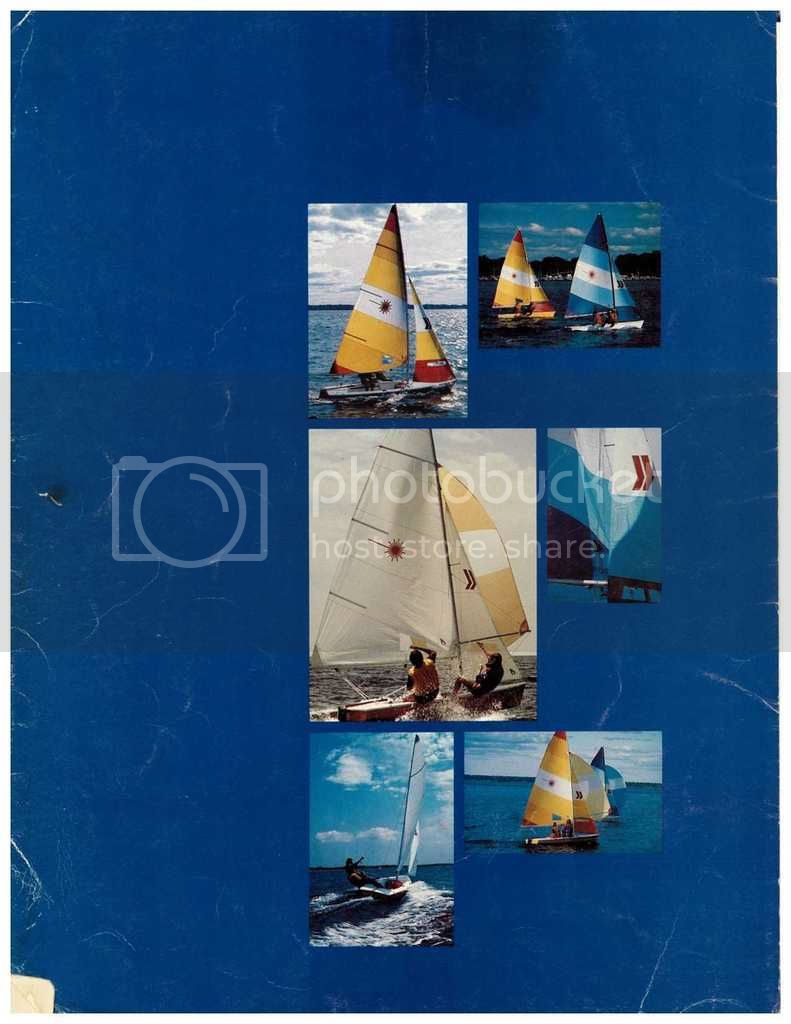

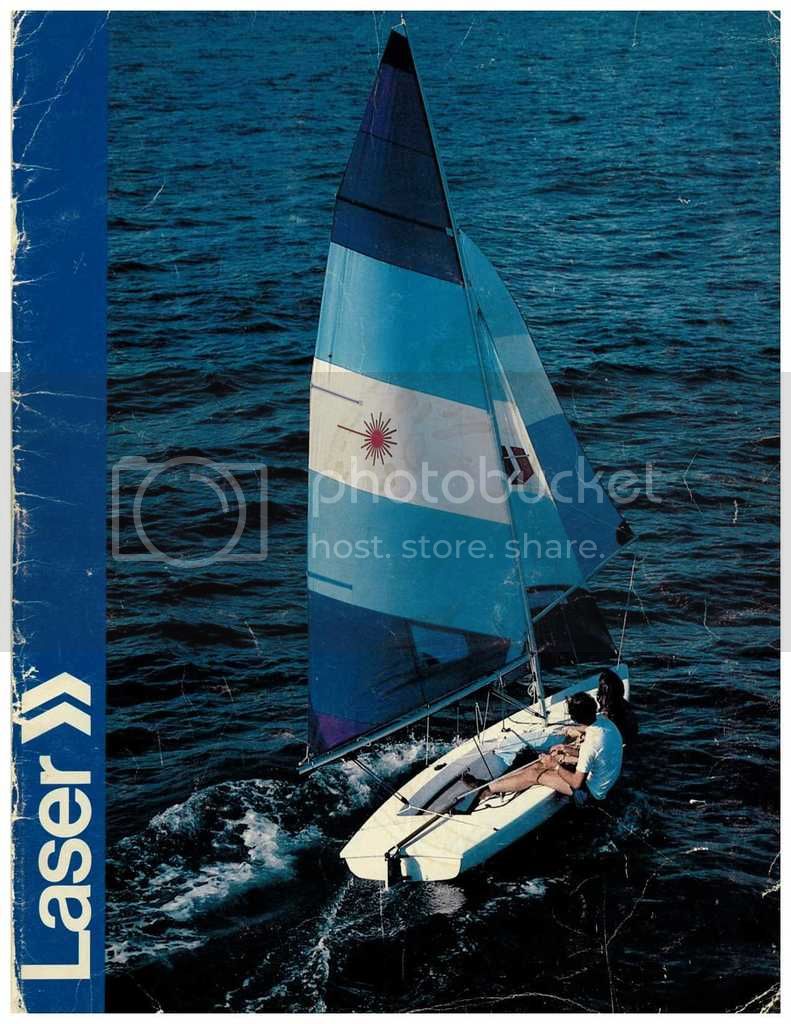

I hunted down the owners manual. No blue hulls. Just the yellow, white, and orange. It looks like the Yellow,"gold",orange, and white sails are pictured on both yellow and burnt orange hulls. I'm guessing that the white sail is the "standard option" on any? For racers? Did people race these with colored sails? The owners manual has some good information. If anybody would like to see a section or part; please ask.

I hunted down the owners manual. No blue hulls. Just the yellow, white, and orange. It looks like the Yellow,"gold",orange, and white sails are pictured on both yellow and burnt orange hulls. I'm guessing that the white sail is the "standard option" on any? For racers? Did people race these with colored sails? The owners manual has some good information. If anybody would like to see a section or part; please ask.

I reduced the remaining gap to a standard 1/4". Oh my! I really cleaned out this damn stuff! I ran out of G-Flex

I reduced the remaining gap to a standard 1/4". Oh my! I really cleaned out this damn stuff! I ran out of G-Flex