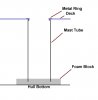

I have just purchased a sunfish made is the 70's by viking. When I got the boat home I realized that the mast tube is badly damaged. Large pieces of the fiberglass are missing and it is no longer attached to the bottom of the hull. I was wondering if anyone had any experience or ideas about for repairing this. I was thinking of constructing a new mast tube from aluminum tubing and attaching it at the bottom of the hull over a circular wood disc that fits the inside diameter of the tube. This disc would be glued to the bottom of the hull. I am going to put in an inspection port about 6 inches from the mast tube, but off center since there seems to be a support fore and aft of the mast tube.

Has anyone heard of a similar repair, or have any ideas?

Has anyone heard of a similar repair, or have any ideas?

I hope it's substantially woven fabric not the window screen looking stuff for muffler repair and holding plaster in drywall patches. The glass fabric is the structure for the resin.

I hope it's substantially woven fabric not the window screen looking stuff for muffler repair and holding plaster in drywall patches. The glass fabric is the structure for the resin.