wjejr

Active Member

Hello fellow Sunfishers.

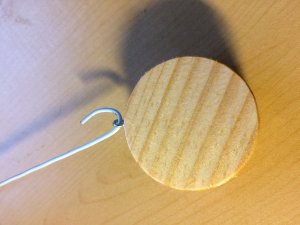

With the rudder all done, I decided to tackle some other SF issues, and first on the list is the leaky mast.

This is the second time I have tackled this job. The first time was only three or four years ago, and although I thought I was careful taking things apart and then putting them back together with Sikaflex as a sealant, the mast now leaks at both ends. It does not leak a lot, but enough to bug me into fixing it.

With the rudder all done, I decided to tackle some other SF issues, and first on the list is the leaky mast.

This is the second time I have tackled this job. The first time was only three or four years ago, and although I thought I was careful taking things apart and then putting them back together with Sikaflex as a sealant, the mast now leaks at both ends. It does not leak a lot, but enough to bug me into fixing it.

Night-time condensation seems to find its way into just about everything anyway.

Night-time condensation seems to find its way into just about everything anyway.