Over the weekend I proceded to cut two holes in my post 1972 Sunfish to install a 6" deck port aft of the splash coaming and a 4" deck port forward of the rudder assembly. Needless to say, I thought I had done sufficient research and study to install these without issue.

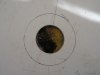

Unfortunately upon cutting my 4" rudder deck port I realized that I had cut a 2" hole (with a circular hole saw) directly over the foam flotation block, exposing a solid block of foam and no free space. My main goal for installing this 4" deck port near the rudder was to aid in the drying of my Sunfish (foam is very water logged).

What is your advice on how to procede from here?

- Should I patch this hole and cut a new hole?

- Can I safety cut into this foam enough to provide for circulation without hurting the integrity of the foam?

- I can see free space just aft of my cut out, should I procede to widen the hole to reach the free space behind the foam?

I attached two pictures to help gauage the situation.

Thanks in advance for all your help.

Unfortunately upon cutting my 4" rudder deck port I realized that I had cut a 2" hole (with a circular hole saw) directly over the foam flotation block, exposing a solid block of foam and no free space. My main goal for installing this 4" deck port near the rudder was to aid in the drying of my Sunfish (foam is very water logged).

What is your advice on how to procede from here?

- Should I patch this hole and cut a new hole?

- Can I safety cut into this foam enough to provide for circulation without hurting the integrity of the foam?

- I can see free space just aft of my cut out, should I procede to widen the hole to reach the free space behind the foam?

I attached two pictures to help gauage the situation.

Thanks in advance for all your help.